Yes V-belts are often used as a guide profile on the running side of a belt to support the straight running of eg. Belt is made by joining.

V Belt Converted To Ribbed Belt Hutchinson Belt Drive Systems

V Belt Converted To Ribbed Belt Hutchinson Belt Drive Systems

Verify the validity of this drive by consulting the number of grooves.

Poly v belt design guide. Special pulleys on request. Are V-belts also used as guide profiles for belts. Optimal speed range is 10007000 ftmin 3002130 mmin.

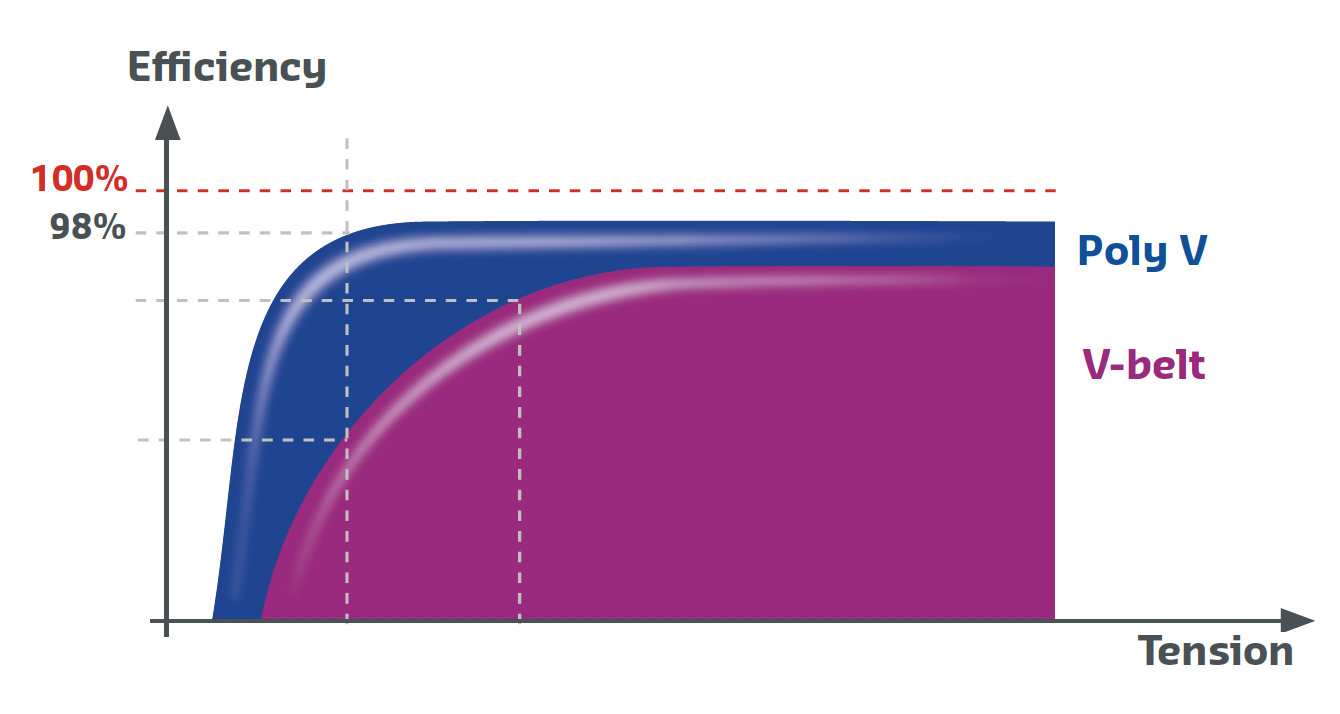

HC Belts and Predator. The V-belts can be designed smooth. Poly-V belts can be up to 98 efficient.

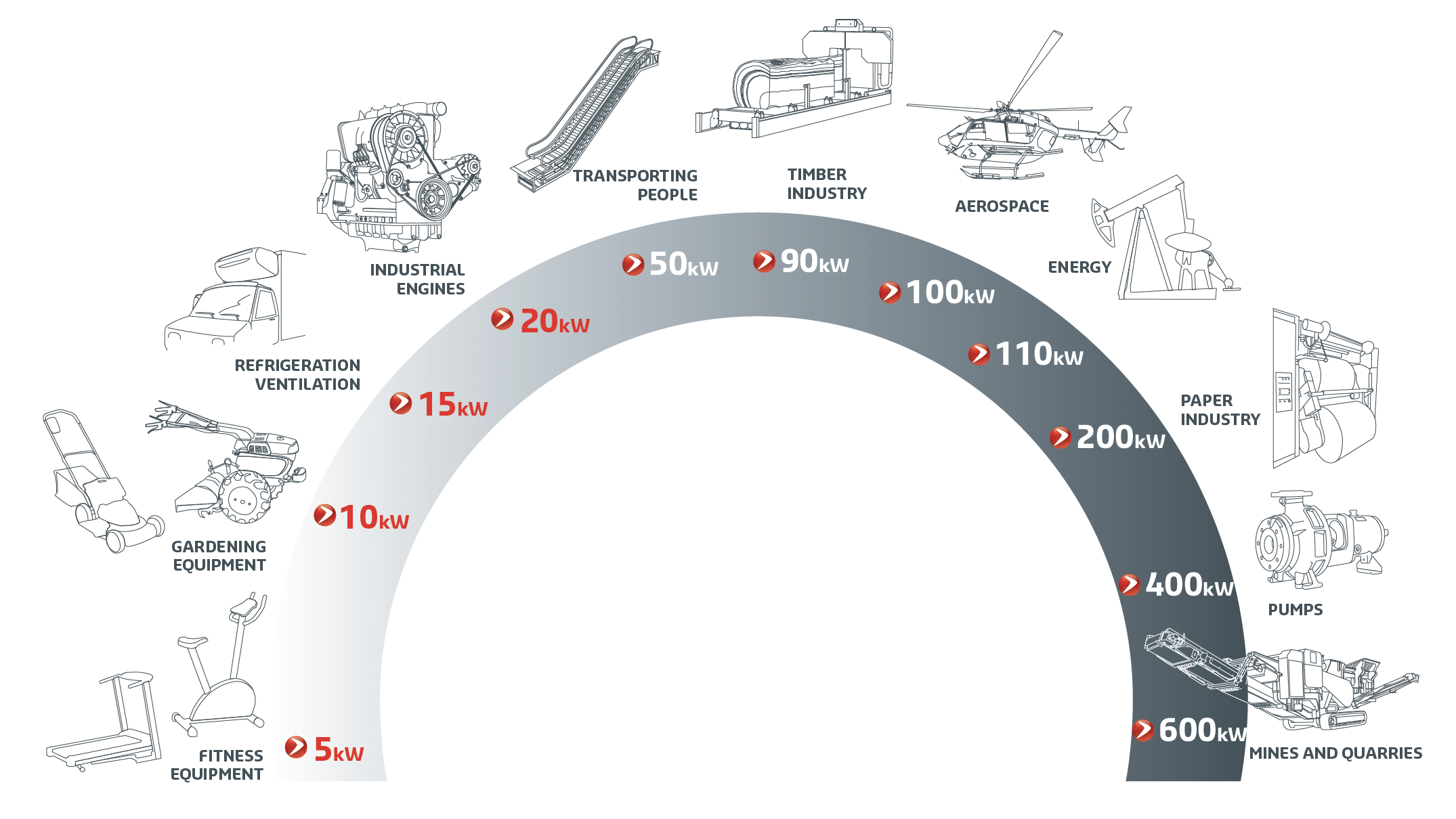

Our Application Technology experts offer you free support service regarding the application of our products and also help. Hutchinson develops and manufactures complete power transmission system incorporating ribbed belts for HVAC Conveying industrial motors agriculture and energy supply markets. Ribbed belt electrically conductive on request Ribbed belt high voltage resistant on request PAK optimised on request Ribbed belt Pulleys Extensive standard range see range list.

If you need assistance designing your drive contact our team of Gates product application engineers. Nearly 100 years ago Gates invented the V-belt constructed with flex-bonded tensile cords to outperform and outlast competitive products. General industrial transmission belts and related products Lists of products.

Timing Belt PDF 8951KB V-BeltJIS PDF 9089KB V-Belt RMA PDF 8599KB V-Belt DIN PDF 5829KB Catalogs. Modern V belts are rubber urethane synthetic and neoprene designs with. Despite their outward similarities each of these belts is designed for a distinct purpose.

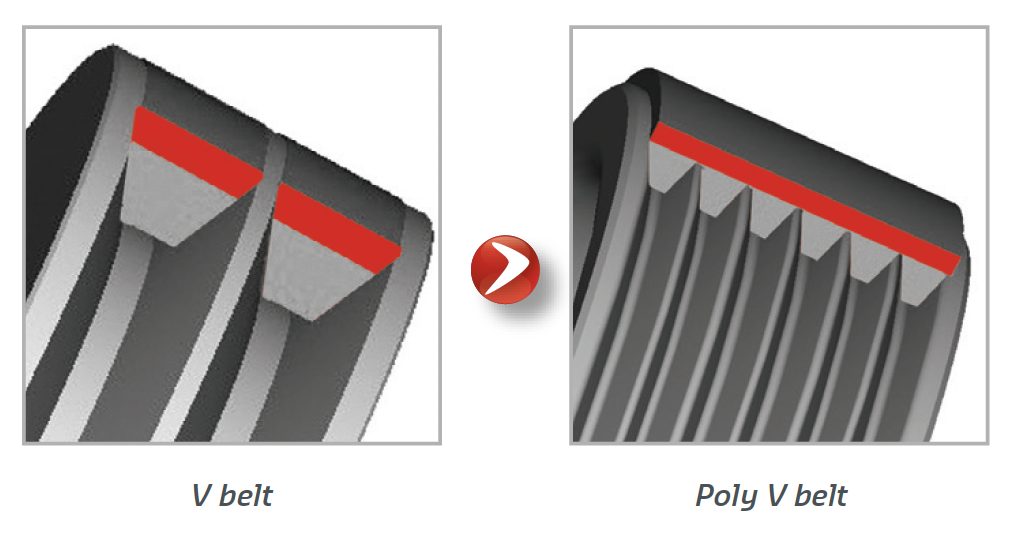

Is a power transmission belt featuring multiple longitudinal ribs. Nominal dimensions of the four cross sections are given in Table 1. To meet all the expectations of the market Hutchinson has expanded its product portfolio with a range of Hutchinson V-belts timing belts and pulleys.

01042008 Find the number of belts required by dividing the design horsepower by the horsepowerbelt value in drive selection tables. Deflection should be 16mm per 100mm of Span length. Please contact our Applications Engineering Department for.

V-belt offerings include Micro-V. Poly-V belts can be up to 98 efficient. For such engines and belts the calculation shall necessarily be made.

Belt lengths depend on the profi le from 250 mm to 2500 mm. This manual includes tables specifications and procedures necessary to design high performance heavy-duty V-belt drives. Due to the single belt design uniform tension is put on the belt across all grooves.

This approach is not relevant for thermal engines and for any other belts Flexonic Conveyxonic. Noise levels can also be reduced by changing over to Poly-V. High speed ratios can be achieved up to 201 with off the shelf sizes and up to 601 with special pulleys.

Dimensions of V-belts and pulleys together with basic design data are covered in this manual. Belt is a single endless belt with longitudinal V-shaped ribs that mate consistently with the V-grooves in the sheaves. High speed ratios can be achieved up to 201 with off the shelf sizes and up to 601 with special pulleys.

Furthermore the V-belts can be applied as an edge limitation instead of corrugated edges. Conveyor belts systems. DEFINE YOUR POLY V BELT ONLINE FIRST APPROACH FOR ELECTRIC ENGINE This approach is only valid for electric engines and Poly V belts.

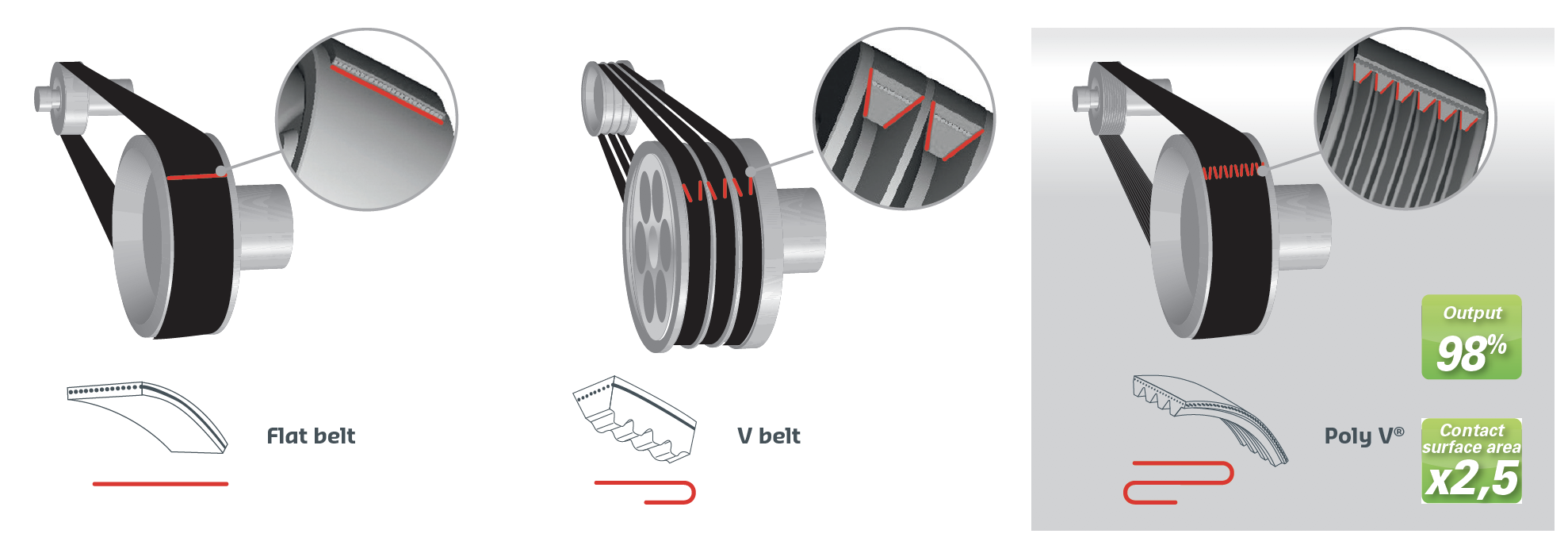

Each of these belts has a 12-inch top width and 50-inch circumference. Gates Predator V-Belts are specially reinforced for demanding applications such as those typically found in the wood and lumber processing industry mining agriculture oil field equipment and heavy construction. It combines the convenience of a thin one-piece flat belt with the strong gripping traction of multiple V-belts to make the Poly-V belt far better than either for many applications.

This Manual Guides You in Designing Drives Using These Gates V-Belts. Nominal Dimensions of V-belt Cross Sections in mm Classical V-Belts 01 Cross Section W H α Features 125 16. Calculate Defl ection load by loading on the center of Span length.

Heavy Duty V-Belt Drive Design Manual. It transmits the torque by contact of the belt rib fl anks and the pulley grooves. Due to the single belt design uniform tension is put on the belt across all grooves.

THE BELT FOR ALL APPLICATIONS Its monobloc design guarantees. These pair a belt with a pulley often on an electric motors geared output shaft to provide reliable operation in myriad end-user and industrial designs. V-Belts which hold up in demanding environments and applications such as oilfield lumber mills and rock crushers.

Compactness Noise reduction Tension stability and reliability High power transmission. Noise levels can also be reduced by changing over to Poly-V. Load on the center of Span length at right angle to the belt with the equipment like a spring balance then check the load.

The preferred center distance is larger than the largest pulley diameter but less than three times the sum of both pulleys. This manual does not apply to automotive and agricultural drives. V-belts need larger pulleys for their thicker cross-section than flat belts.

Long andor narrow conveyor belts or to absorb transverse forces in case of lateral product feed. 15082017 The earliest belt iteration and one thats still economical today is the friction-based V-belt design. However notice the differences in cord materials body compounds cover configurations temperature ranges and application requirements.

TECHNICAL MANUAL V-BELT DRIVES This technical manual contains all important technical information and methods for the design and calculation of drives with Optibelt V-belts and V-grooved pulleys for industrial applications. MegaTorque EXG II PDF 1467KB GigaTorque GX PDF 1944KB Smart Tension PDF 542KB Page Top. This new generation PowerBand.

How To Replace V Belt Serpentine Tali Kipas Honda Crv Civic Hrv R20a1 Youtube

How To Replace V Belt Serpentine Tali Kipas Honda Crv Civic Hrv R20a1 Youtube

Poly V Belt For Industry Hutchinson Belt Drive Systems

Poly V Belt For Industry Hutchinson Belt Drive Systems

V Belt Converted To Ribbed Belt Hutchinson Belt Drive Systems

V Belt Converted To Ribbed Belt Hutchinson Belt Drive Systems

V Belt Pulleys Selection Guide Types Features Applications Engineering360

V Belt Pulleys Selection Guide Types Features Applications Engineering360

China Oft Cogged V Belt Raw Edge V Belt High Flexibility V Belts Rubber Drive Belt China Transmission Belt Raw Edge V Belt

China Oft Cogged V Belt Raw Edge V Belt High Flexibility V Belts Rubber Drive Belt China Transmission Belt Raw Edge V Belt

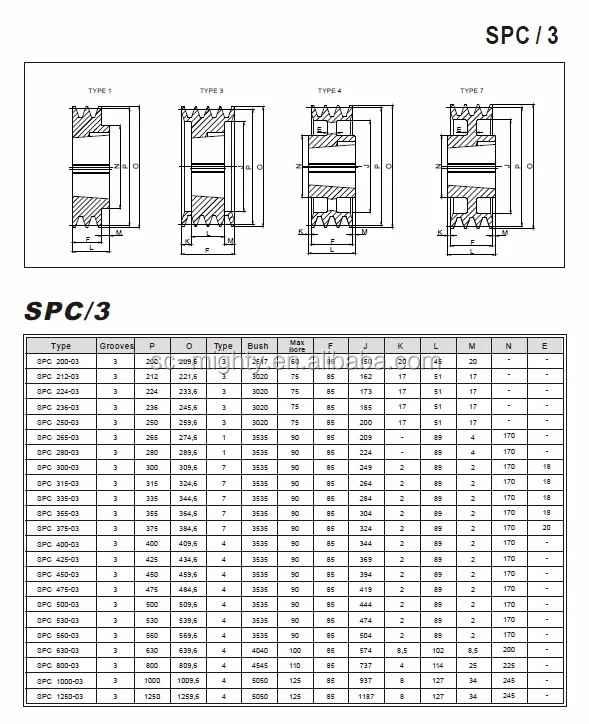

5 Groove Poly V Belt Pulley For V Belt Standard Sizes Buy 5 Groove Pulley Poly V Belt Pulley V Belt Standard Sizes Product On Alibaba Com

5 Groove Poly V Belt Pulley For V Belt Standard Sizes Buy 5 Groove Pulley Poly V Belt Pulley V Belt Standard Sizes Product On Alibaba Com

V Belt Code Guide Spec Sense Youtube

V Belt Code Guide Spec Sense Youtube

Poly V Belt For Industry Hutchinson Belt Drive Systems

Poly V Belt For Industry Hutchinson Belt Drive Systems

China 3pk 4pk 5pk 6pk 7pk 8pk 9pk 10pk 11pk 12pk Rubber Poly Ribbed V Belt Serpentine Pk Belt China Poly V Belt Pk Belt

China 3pk 4pk 5pk 6pk 7pk 8pk 9pk 10pk 11pk 12pk Rubber Poly Ribbed V Belt Serpentine Pk Belt China Poly V Belt Pk Belt

5 Groove Poly V Belt Pulley For V Belt Standard Sizes Buy 5 Groove Pulley Poly V Belt Pulley V Belt Standard Sizes Product On Alibaba Com

5 Groove Poly V Belt Pulley For V Belt Standard Sizes Buy 5 Groove Pulley Poly V Belt Pulley V Belt Standard Sizes Product On Alibaba Com