Chain drive is usually not affected by workroom temperature. High mechanical efficiency as much as 98 when properly maintained.

Chains Vs Belts Comparison Which Is The Best For Cyclists

Chains Vs Belts Comparison Which Is The Best For Cyclists

This drivetrain eats up more space.

Belt drive v chain drive efficiency. Disadvantages of Belt Drive. They give a high transmission efficiency of up to 98 percent. 05112020 Belt Drive Motorcycle Image Source Belt Drive is Useful.

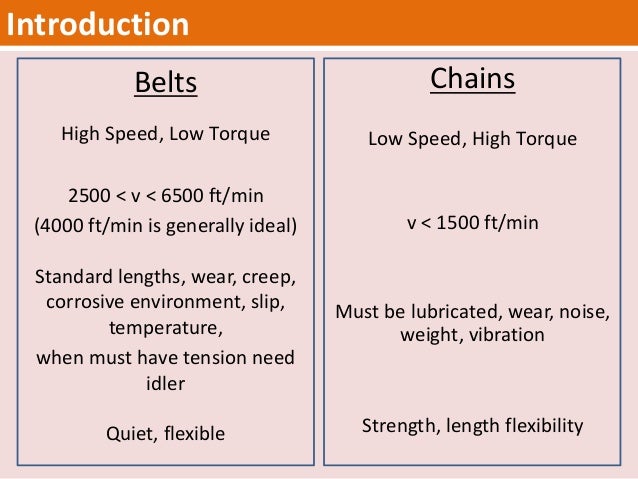

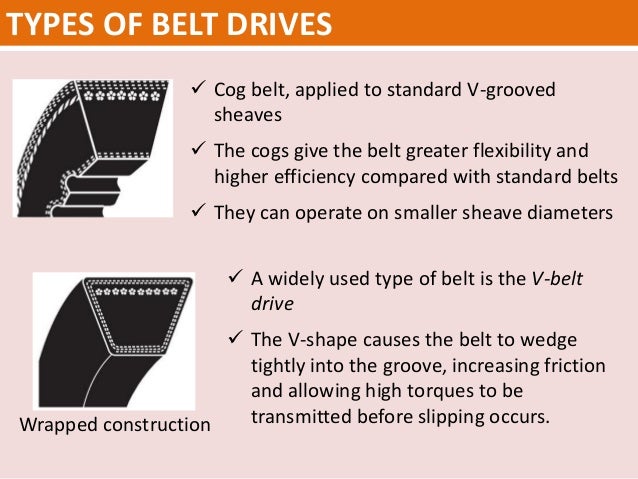

The level of energy savings achieved by the replacement of plain-base wrapped V-belts with cogged V-belts is emphasized. 20042020 Belts are less efficient at low power inputs-If youre just cycling casually youll burn more energy while riding a belt drive bike vs a chain drive. A belt is a flexible power transmission element that runs tightly on a set of pulleys.

Its tooth engagement eliminates belt. The disadvantages of chain drives. After installation V-belt drives that are not retensioned or properly maintained may run at efficiencies as low as 85 to 90.

Shaft drives come up last with their high weight and heavy gear oil. 29102012 Chain drives can operate in high temperature and moist conditions but belt drives cannot. Chain drives do not deteriorate due to sunlight oil grease or age.

Belt drives may cause the bottom bracket and rear hub to wear out faster-This happens because belts run at a much higher tension than chains. Cogged belts These types of belt drives have slots that run perpendicular to the belts length helping to reduce the bending resistance of the belt. The drive is positive because the slip between the belt and the pulley groove is negligible.

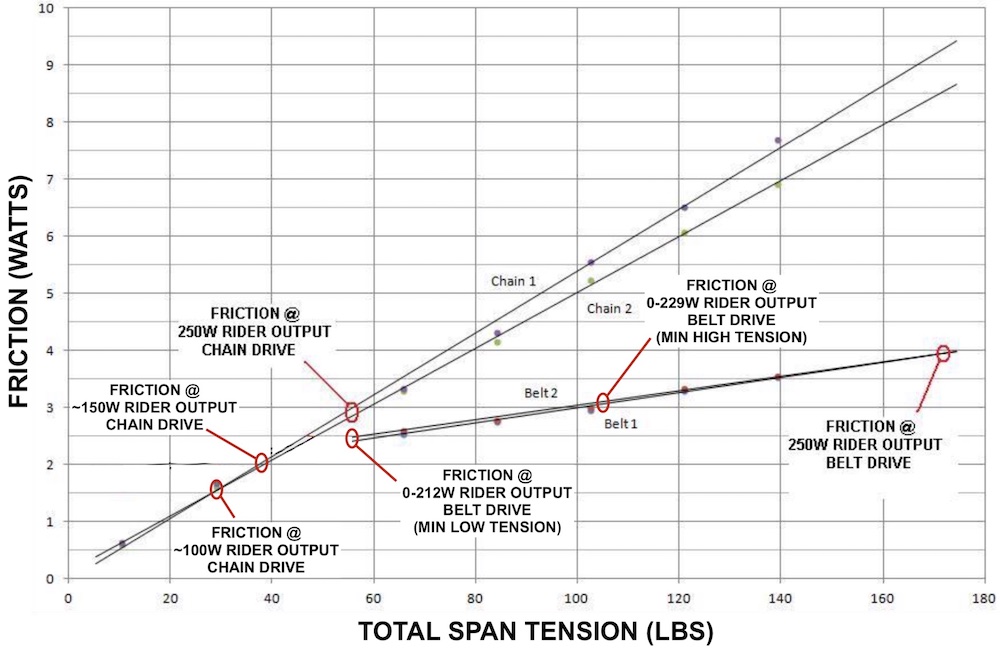

These last longer as high as 100000Kms. 19082019 V-belts have a nominal efficiency of 93 a reduction of 5 over time if slippage occurs because the belt is not periodically re-tensioned. Even if its only marginally more efficient than a chain drive it will take less energy to turn a properly fitted belt rated for the same power.

Since the v-belt are made endless and there is no trouble therefore the drive is smooth. 14122015 a conventional chain drive consumes 292 watts on average while the belt eats up 393 watts. By contrast chain drives are in the 91-98 efficiency range while V-Belts average in the 93-98 range.

Today there are many kinds of drives including the V-belt cogged belt and synchronous belt. It provides longer life 3 to 5 years. Although the difference is just 1 watt not enough for most people to care this works out as a substantial 346 percent.

More compact and are easy to install compared to belt drive. Are less noisy and have fewer vibrations. Belt drives are some of the common devices for transmitting motion from one shaft to another using pulley system.

They weight way less than a chain drive. This extra tension puts more stress on the bearings in the bottom bracket and rear. Chain drives have low maintenance cost.

Belt efficiency slip and temperature dependence on the basic. Negligible friction loss results higher efficiency in chain drive 95 98. They have fewer transmission losses.

01022005 V-belts are also less efficient than chain or synchronous belt drives. Belt drives undergo slippage whereas chain drives have no slippage. The most important.

Data is documented for Vee joined-V V-ribbed and synchronous belt types and for cogged plain and laminated V-belt constructions. Belt drives are not lubricated whereas the chain drives are lubricated. Power transmission efficiency is not lost with use Clean operation no need for lubrication.

Lower load on shaft than belt drives. 13072020 The v-belt drive gives compactness due to the small distance between the centres of pulleys. A chain drive consists of a series of pin-connected links that run on a set of sprockets.

According to Jason Smith at Friction Facts the answer is no. This lab test has determined that chains are between 03 and 10 more efficient at low power outputs under 212 watts while belts are more efficient at high power outputs over 212 watts. They can only function up to a certain speed.

Gears Belts and Chain are some of the transmission elements used for transmitting power to the required part. 01032000 For example a synchronous belt drive though initially more expensive delivers high efficiency about 98 with minimal attention. Based on the requirement of the application and economic the designer will choose the transmission needed Belts.

For maximum efficiency a belt drive is the right way to go. 02012013 But is it more efficient than a conventional chain drive. The system comprises of a looped strip from a flexible material that help link rotating shafts.

By his measurements a conventional chain drive. Things get a bit more muddied for the chain when we factor in different chain lubricant options. They can operate even in wet conditions.

Chain drives use sprocket while belt drives use sheaves pulleys. Belts are efficient in transmitting power. 27112018 Due to friction loss efficiency of belt drive is comparatively low 92 96.

Workroom temperature influences performance of belt drive.

Are Belt Drivetrains More Efficient Than Chain Drivetrains Lab Testing Cyclingabout

Are Belt Drivetrains More Efficient Than Chain Drivetrains Lab Testing Cyclingabout

Selecting The Right Drive System Cost And Performance Je Bearing

Difference Between Chain Drive And Belt Drive Difference Between

Difference Between Belt Drive And Chain Drive

Difference Between Gear Drive And Chain Drive

Chain Drive Vs Belt Drive Vs Shaft Drive Motorcycle Drivetrain Explained

Chain Drive Vs Belt Drive Vs Shaft Drive Motorcycle Drivetrain Explained

Mechanical Notes Machine Design Belt Drive

Mechanical Notes Machine Design Belt Drive

Difference Between Flat Belt Drive And V Belt Drive

Are Belt Drivetrains More Efficient Than Chain Drivetrains Lab Testing Cyclingabout

Are Belt Drivetrains More Efficient Than Chain Drivetrains Lab Testing Cyclingabout

What Is Chain Drive Advantages And Disadvantages Of Chain Drive Over Belt And Rope Drive Mecholic

What Is Chain Drive Advantages And Disadvantages Of Chain Drive Over Belt And Rope Drive Mecholic