I promptly forgot the angle that we came up with but i think it was 37 degrees. Some narrow v-belts can operate at speeds of up to 10000 ftmin but these pulleys must be dynamically stabilized.

Langkah Pemasangan V Belt Yang Benar Niagakita

Langkah Pemasangan V Belt Yang Benar Niagakita

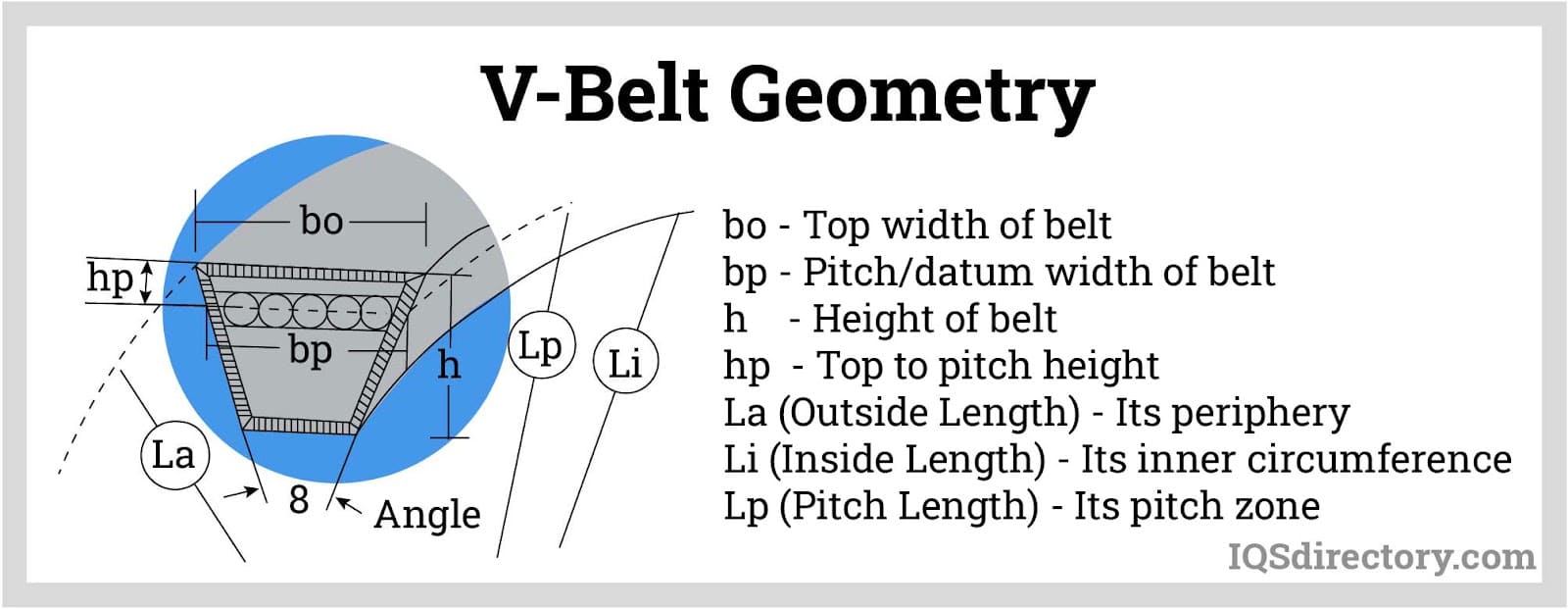

T Maximum tension in belt T 1 T 2.

V-belt angle of contact. 12112011 no definitive answer but both concur that it appears to them that all v belts share the same angle. θ b Angle of contact at pulley B. A V-belt may be used in combination with a drive sheave on a motor shaft and a pulley on the driven shaft.

The included angle. Formula 2 below establishes the static tension required to. Angle of contact for a cross belt drive is the angle made by the portion of the belt which is in contact with the pulley.

17112020 Q10 The groove angle of pulleys for V-belt is. Use for large pulley and X-belts. These belts are moulded to a trapezoidal shape and are made endless.

B 12 groove angle C distance between shafts in D 1 sheave diameter D 2 sheave diameter L Length m massunit length of belt Angle of contact. If anyone has a better answer i too would like to know and the source of the info. Sheaves have a V-groove.

22022010 The included angle of the V-Belts is 40 Degrees. Width Metric V Belts. T 0 Initial tension in belt T 1 T 22.

Pulleys have a flat circumference. Twisted synthetic fibrous tensile chords compressed by synthetic rubber form a typical V-belt rendering it strength and flexibility. 24042017 The groove angle of the pulley for V-belt drive is usually a.

Tension of V-belt. Section A Type -. A standard belt b.

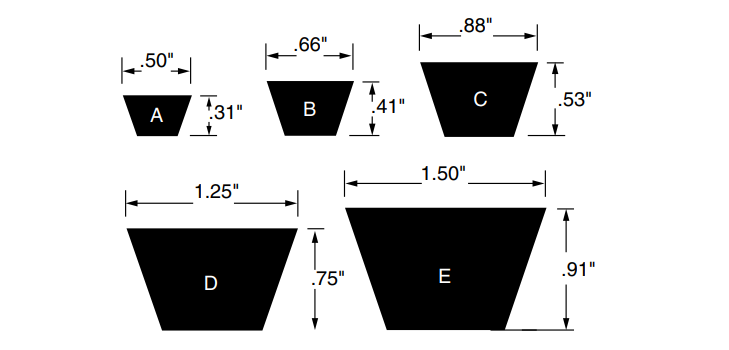

V Belt has a trapezoidal cross-section. Width BB Section Dbl Angle 58. Tension of flat belt.

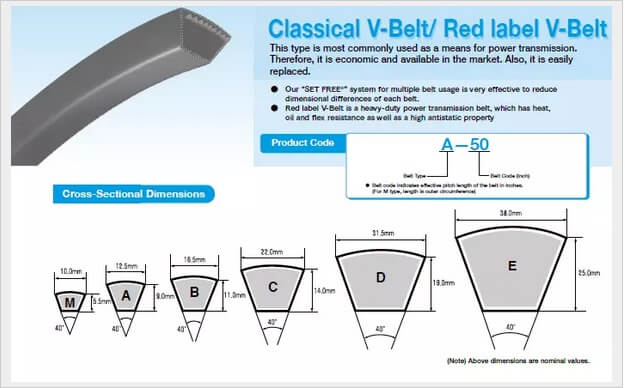

Classical Wedge narrow and FHP fractional horsepower. 91 7900123134 Email id. 23122016 V belt drives 1.

This is because power capacities are based on the standard of a 180. Width CC Section Dbl Angle 78. θ a Angle of contact at pulley A.

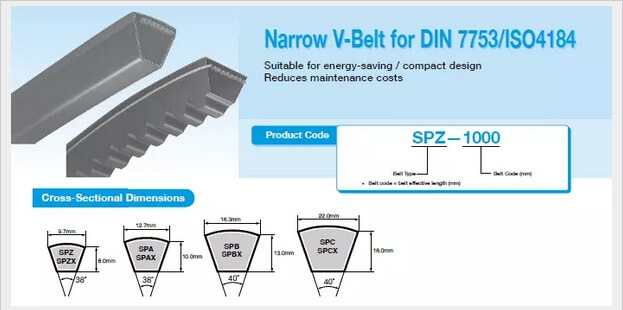

SPZ Section Metric 10mm Width SPA Section Metric 13mm Width SPB Section Metric 17mm Width SPC Section Metric 22mm Width Micro Rib Belts. A V-belt designated by A-914-50 denotes a. Q11 The included angle between the sides of V-belt is.

Service factor c 2. Arc of contact correction factor c 1 The arc of contact correction factor corrects the power rating of the V-belt for pulleys where the arc of the contact differs from 180 degrees. The size of the correction factor is determined from the following equation.

L c Length of belt in cross-drive. L 0 Length of belt in open belt drive. AA Section Dbl Angle 12.

KPK Series Serpentine Variable Speed Belts. Heres is a brief outline on the power transmitting capacity of the each section type of the belt. In large speed ratios or small central distances the angle of contact between the belt and pulley may be less than 180.

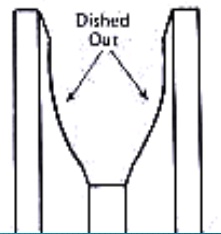

V-belts are used to transmit power from motors to machinery. Angle of contact dependent on pulley diameters and the center distance Centrifugal force lifting the belt off the pulley produced by the rotation of the pulley Angle of the V in the pulley which wedges the belt in place Wedging Effect V-Belts largest advantage over. Q15 The stress induced in the belt is.

Equation and Calculator to determine the v-belt angle between the two sheave pulleys. Velocity Ratio Of Belt Drive Belts Ropes. This ratio changes with the angle of contact on the small sheave.

34 36 degree. Rated power of belt. Angle 38 degrees it can be shown that at 180 degrees of wrap a practical level of V-Belt operating tension can be achieved with a 51 ratio between the tight side tension and the slack side tension.

An undersize belt d. T 2 Slack side tension. T 1 Tight side tension.

Chain Drives Kinematics of Machinery. L Center distance between the driving and the driven pulley. Belt length open Belt length closed Angle of contact Note.

There are three common types of v belts. The V-belts are made of fabric and cords moulded in rubber and covered with fabric and rubber as shown in Fig. More then 40 0.

It is used to transfer a high amount of power between short distances. 42 45 degree. V-belt is mostly used in factories and workshops where a great amount of power is to be transmitted from one pulley to another.

The exact transmission power of the belt will vary based on other criteria like arc of contact speed ratio etc. If this is the case the drive power must be further increased according to manufacturers tables and the selection process repeated. Typically v-belt drives operate between 1500 to 6000 ftmin with 4500 ftmin the ideal capacity for standard belts.

30 32 degree. The belt length is usually less and there is less chance of slippage in cross belt drive. The angle of contact is more in a crossed belt drive.

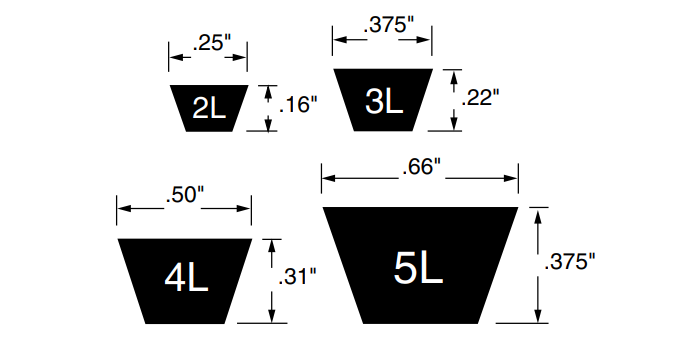

This type of belt is used with grooved pulleys. Only depth and width are the variables. Double Angle V Belts.

Cross belt drive have higher Power of transmission than open belt. An oversize belt c. These are particularly suitable for short drives.

It is always greater than 180 for a cross belt. In case of open belts it is less than 180. V-belts get their name from their trapezoidal shape which helps them wedge into the sheaves.

None of these 39.

Gates A35 Hi Power Ii V Belt 90022035 V Belt Belt Power Gate

Gates A35 Hi Power Ii V Belt 90022035 V Belt Belt Power Gate

The Common Types Of V Belts Their Standard Sizes

The Common Types Of V Belts Their Standard Sizes

High Quality Grinding Wheel Grinding Pulley For Grinding And Shaping The Rib Or Profile For Power Transmission Belt V Belt Poly Power Transmission Edges

High Quality Grinding Wheel Grinding Pulley For Grinding And Shaping The Rib Or Profile For Power Transmission Belt V Belt Poly Power Transmission Edges

Jenis Dan Type V Belt Pertanian Industrial V Belt

Jenis Dan Type V Belt Pertanian Industrial V Belt

The Common Types Of V Belts Their Standard Sizes

The Common Types Of V Belts Their Standard Sizes

V Belt What Is It How Does It Work Types Of Uses

V Belt What Is It How Does It Work Types Of Uses

Https Practicalmaintenance Net Wp Content Uploads Construction Installation And Maintenance Of Power Transmission V Belt Drives Pdf

Penghitung Ukuran Sabuk V Panjang Dan Nomor Sabuk Arsip Teknik

Penghitung Ukuran Sabuk V Panjang Dan Nomor Sabuk Arsip Teknik

Jenis Dan Type V Belt Pertanian Industrial V Belt

Jenis Dan Type V Belt Pertanian Industrial V Belt

A A Two Pulley Belt Drive B Free Body Diagrams Of The Belt On The Download Scientific Diagram

A A Two Pulley Belt Drive B Free Body Diagrams Of The Belt On The Download Scientific Diagram