Each of these belts has a. 01062000 Coaxing V-belts to operate more efficiently A poorly operating belt drive can easily waste 10 of its input horsepower.

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

01062006 If you are working with a V-belt design then you will need to tension the belt manually.

How to make a v-belt longer. Then cut off the excess push the metal splice into the other end of the belt and stretch it over the pulleys. Classical Wedge narrow and FHP fractional horsepower. Pristine accuracy will best help you achieve belt longevity ultimately saving you money.

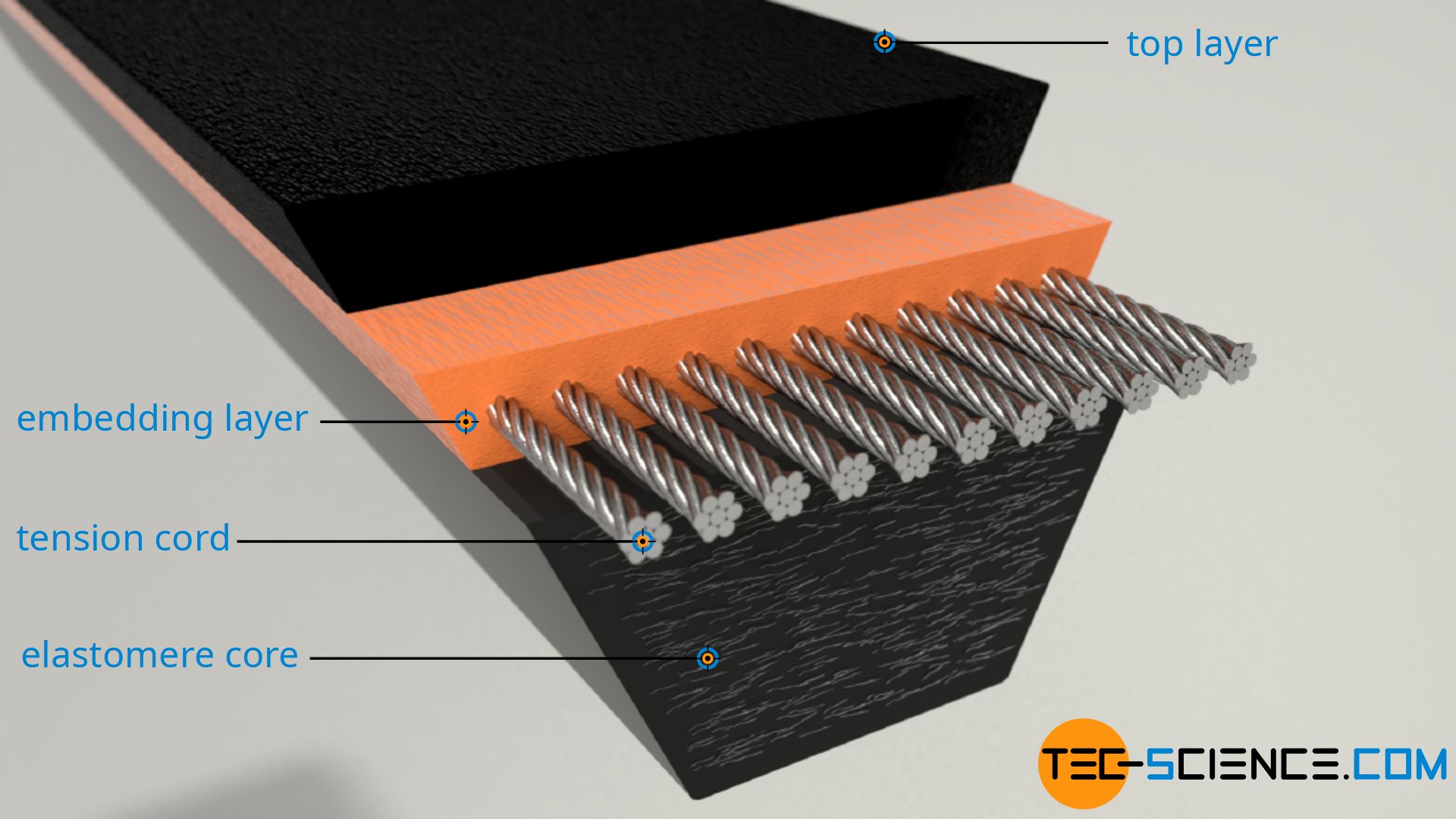

A Belt Tension Meter is a hand-held device that has two elements. Knowing the factors that affect how these belts operate will give. Twisted synthetic fibrous tensile chords compressed by synthetic rubber form a typical V-belt rendering it strength and flexibility.

And for every 2 F increase in ambient temperature there is a 1 F increase in the belts internal running temperature. 27112006 If there is any concern over the rigidity of the structure make sure that the synchronous sprockets are the same size or larger than the V-belt sheave diameters. The common configuration shown has the crankshaft pulley driving the water pump vital for cooling and alternator charges the battery with V-belt A and the power steering pump and AC compressor driven by the crankshaft pulley and V-Belt B.

11052018 See all 9 photos Lets begin the next step with a longer-than-necessary used V-belt. Without loosening or removing parts from the car. To install you simply thread the belt around the pulleys to measure the exact length.

There are three common types of v belts. This keeps the belt pull roughly equal to that of the existing V-belt drive while minimizing the possibility of structural deformation. How to Sneak in a V-Belt V-Belts are commonly used to drive the accessories on the engine of a car.

Thus each 18 F increase in internal belt temperature cuts the belt life in half. 01042008 This causes vibration noise and reduced life. Move that point from side to side and the belt should have 12 inch 13 cm of movement in either direction.

In this article well review some V-belt basics to help you make better sense of which belt to use in a given ap-plication to make your belt drives last longer run more efficiently and save you downtime and money. Size Isnt Everything Take a look at the accompanying chart Figure 1. An optical sensor and a meter.

High loads high temperatures incorrect tensioning worn sheaves misalignment and dirt oil and grease between the belt and the sheaves are all things that damage the efficiency and the. Since the diameters and belt length are discrete variables so also is the theoretical centre distance though in the absence of idlers the nominally fixed. Sheave balancing on V-belt drives fixes this by altering the center of gravity to correspond with.

Temperature V-belt service life is cut in half. With the belt standing up with the outer flat part on the desk put the belt mark on the desk mark and roll the belt along the desk till the belt mark touches the desk again then mark that point. The whole operation can be done in less than 5 min.

This method is IBTs recommended choice for precision tensioning and time efficiency. Each cord is individually and specially coated to secure a long-lasting bond with the surrounding rubber and to grant a longer operational lifetime. Any less and the belt is too tight any more and it is too loose.

05022018 2 HOW TO TENSION A V-BELT USING A BELT FREQUENCY METER. 16042020 Check the part number on it its usually the belt length in mm. 18052020 Many mechanics dont do this but it is a really important step in substantially increasing the life of your V-belt.

Gates V-belts are engineered to run maintenance-free to keep your vehicles moving without the need for lubrication or retensioning. V-belt drives are essentially short centre drives. Find the middle of the belts longest stretch.

Weve designed our V-belts for wear corrosion and heat resistance with OE quality fit and construction for reliable long-lasting performance. To maintain horizontal angular alignment its best to use a laser tool. The tensile section is made up of a multiple number of high-strength low elongation polyester cords completely embedded in the adhesion layers to enhance resistance to tension and ex-fatigue.

V-belts get their name from their trapezoidal shape which helps them wedge into the sheaves. With the alternator snugged in the desired position the. Also when measuring a belt put a mark on it and put a mark on a table.

If in drive design the centre distance C is not specified then it should be set at around 2D 1 R1 but preferably not less than D 2.

Types Of Belts For Belt Drives Tec Science

Types Of Belts For Belt Drives Tec Science

Pin On Industrial And Automotive Belts

Pin On Industrial And Automotive Belts

Pin On Vee Belts And V Belt Pulleys For Sale

Pin On Vee Belts And V Belt Pulleys For Sale

A Timing Belt Belt How To Wear Belts Belt Timing Belt

A Timing Belt Belt How To Wear Belts Belt Timing Belt

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

How To Tension A V Belt How Not To Ibt Industrial Solutions Ibt Industrial Solutions

V Belt Code Guide Spec Sense Youtube

V Belt Code Guide Spec Sense Youtube

V Belts Vee Belts Drives Distributor Minneapolis Mn Rapid City Sd

V Belts Vee Belts Drives Distributor Minneapolis Mn Rapid City Sd

Top 8 Causes Of V Belt Failure Insight Acorn Industrial Services Ltd

Top 8 Causes Of V Belt Failure Insight Acorn Industrial Services Ltd

3 Ways To Quiet A Noisy Fan Belt Wikihow

3 Ways To Quiet A Noisy Fan Belt Wikihow

Pin On Fasteners Capital Bolts

Pin On Fasteners Capital Bolts

7 Tips For Best V Belt Performance How To Prevent Slipping And Other Belt Issues 052 Youtube

7 Tips For Best V Belt Performance How To Prevent Slipping And Other Belt Issues 052 Youtube