Belts do so much to keep your equipment running smoothly. Belts can be noisy.

V Belt Drive Advantages And Disadvantages Mecholic

V Belt Drive Advantages And Disadvantages Mecholic

Belt was crimped before fitment.

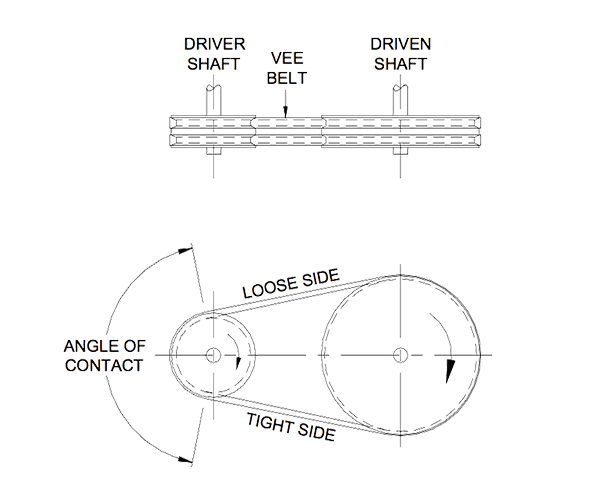

Main cause of v belt drive issues. This carryback can also cause safety issues down the road because excessive material buildup can be a fire hazard and certain materials can be dangerous if frequently inhaled. Foreign object between the belt and pulley will break the tensile cords. 1 Straight cord line rupture.

Increase belt wrap on drive pulley. Also loose or worn belts can be a major cause of machinery vibration. In fact a V-belt that is over-tensioned by 10 percent can produce a 10 percent reduction in bearing life of the motor and over-tensioning is also the leading cause of V-belt failure.

Belts fail to carry a load No visible reason shown. Make sure drive pulley is free of build up. Or belt was twisted over 90.

26012019 In more severe instances a bad tensioner pulley can cause the drive belt to break. Belt rolled or pried onto sheave. Failure of the Belt-driven Accessories to Operate.

If you want to avoid early comebacks misalignment must be found and corrected before installing a new Micro-V belt. Disadvantages of Belt Drives. Belt tension that is too loose or too tight leads to inefficient power transmission belt wear belt failure and possible premature motor failure.

This video provides step-by-step repair instructions for replacing the drive belt or v-belt on a Craftsman riding lawn mower. 29032018 While it may not seem like much this material will increase and lead to accumulation underneath your belt causing problems with your rollers and pulleys. Its a weak sometimes barely noticeable squeaky sound that may even disappear when you start to drive or the engine heats up a bit.

The most common reason for re. Check them regularly to avoid serious problems. 09022015 Lawn Mower Belt Problem Reference Chart.

Wr ong Belt Cr oss-Section or Type. Excessiv e Oil or Gr ease. While belts require very little maintenance improper belt tension misalignment of pulleys mishandling of belts and environmental factors are common problems that can shorten the life of your belts and bring your system.

Increase tension at screw take-up. Provide adequate guards or drive protection methods. Refer to Tables 1 and 2 for values Tensioning the New V-Belts With the sheaves or idler moved to minimum center distance for belt removal as described above the new belts can be.

Broken belts Under-designed drive. Insufficient traction between belt and drive pulley. Increase weight on gravity take up.

Indicates other possible causes Belt Slips Squeals Spin Burn W o rn or Dama g ed Shea ve s Insufficient T ension. Theres a lot to be said about the damage that can be caused from forcing a belt onto a pulley or running your v-belts with the incorrect tension as this is the most common cause for many types of belt damage including cover splits. Since the belt tensioner keeps the proper spinning of the drive belts in the cars engine certain components or accessories may fail to operate if theres a problem with the tensioner.

Excessiv e Moistur e. Belts cannot be used where exact timing or speed is required because slippage does occur only timing belts can be used. 05042018 Belts along with electric motors shafts and pulleys are a critical component of power transmission in belt drive systems.

Redesign the drive to accommodate shock load. Belts are easily damaged by oil grease abrasives some chemicals and heat. The slipping is caused because the belt loses ability to produce enough friction between itself and the pulleys mostly due to material fatigue.

25062015 Misalignment can also create belt routing problems excessive wear noise and belt stability problems which can all cause your customer to come back to the workshop thinking the belt you installed failed. Shorten the center distance of the drive until the belts can be put on the sheaves without forcing. Use of Belt Dr essing V -Belt Troubleshooting Guide SYMPT OMS CA USES Indicates most common causes.

2 Raffled cord line rupture. Object falling into drive. Use drive take-up when installing.

Thats why its important to keep them working in peak condition. Squeaking is caused because the belt is slipping over the pulleys. The chart below shows some possible signs of belt problems and solutions.

Forcing the belts can cause internal injury to the belts. Or turned inside out before fitment or forced on. Pulley lagging is worn or not adequate to produce sufficient traction.

Twenty Three Short Answer Questions On Power Transmission Engineering Tutorials

Http Practicalmaintenance Net Wp Content Uploads Construction Installation And Maintenance Of Power Transmission V Belt Drives Pdf

Gates V Belt Alignment Belt Misalignment Minneapolis Belts Distributor

Gates V Belt Alignment Belt Misalignment Minneapolis Belts Distributor

V Belt Vs Synchronous Belt 5 Reasons To Upgrade Your Belt Drive Ibt Industrial Solutions Ibt Industrial Solutions

V Belt Vs Synchronous Belt 5 Reasons To Upgrade Your Belt Drive Ibt Industrial Solutions Ibt Industrial Solutions

Installation Tensioning Maintenance Of V Belts National Air Filtration Association

Installation Tensioning Maintenance Of V Belts National Air Filtration Association

What Are The Advantages Disadvantages Of V Belt Drive Over Flat Belt Drive Quora

Robotic Mechanisms Pulleys And Belts 51045 Robotpark Academy

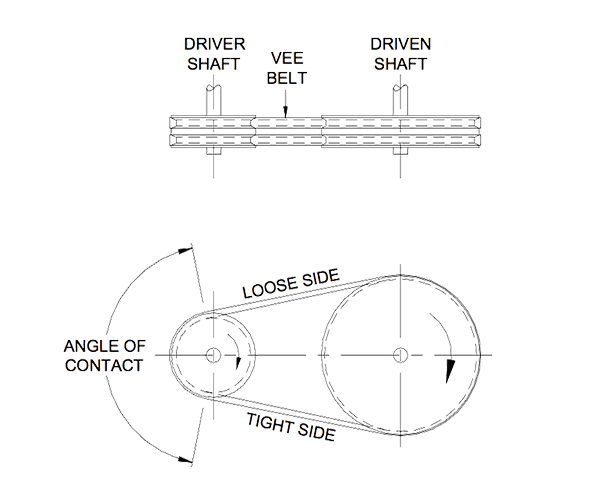

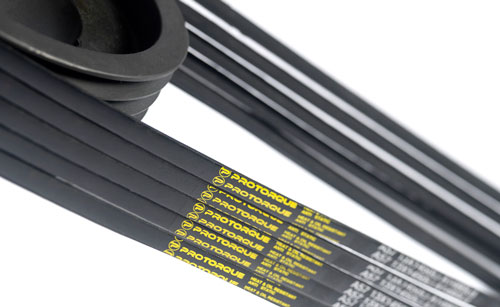

Vee Belt Drives Basics And Considerations Accendo Reliability

Vee Belt Drives Basics And Considerations Accendo Reliability

What Is Belt Drives Type Advantages And Disadvantages

What Is Belt Drives Type Advantages And Disadvantages

Belt Tension An Overview Sciencedirect Topics

Belt Tension An Overview Sciencedirect Topics

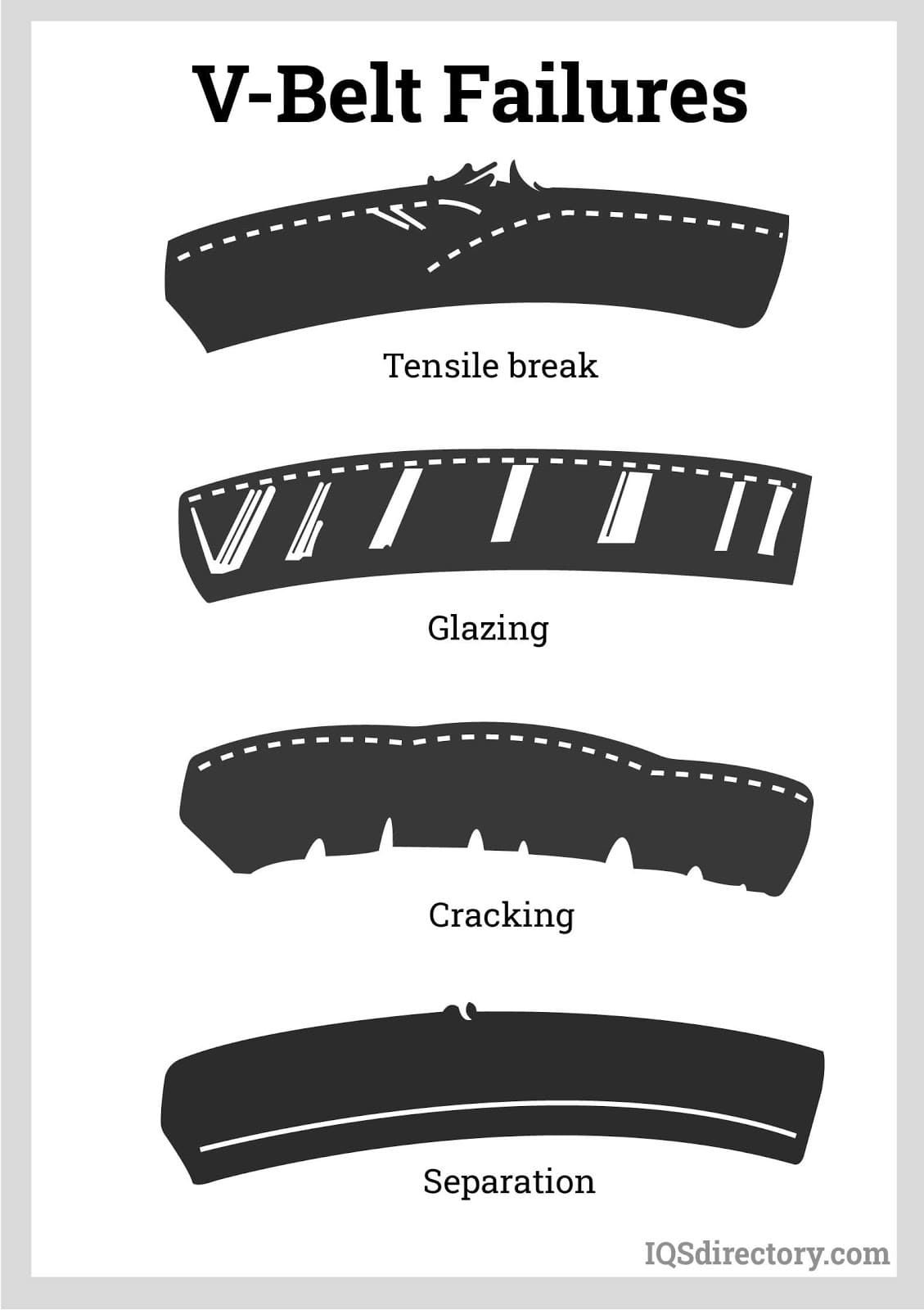

V Belt What Is It How Does It Work Types Of Uses

V Belt What Is It How Does It Work Types Of Uses

Top 8 Causes Of V Belt Failure Insight Acorn Industrial Services Ltd

Top 8 Causes Of V Belt Failure Insight Acorn Industrial Services Ltd

V Belt What Is It How Does It Work Types Of Uses

V Belt What Is It How Does It Work Types Of Uses