Flat belt V belt and synchronous belt. Typically V-belts and V-ribbed belts are used with mating pulleys in drives where speed ratio is not critical.

14102020 V belts are arguably the most widely used belts in the industry.

What is a v belt used for. It is now the basic belt for power transmission. FHP light duty V-belts are used most often as single belt on drives of 1 horsepower or less. A joined V-belt is in essence a number of single V-belts joined togeth-er with a continuous tie-band across the back see Figure 8.

V-belts are the most widely used belt drives since their geometry causes them to wedge tightly into the groove as the tension is increased. A v-belt is a flexible machine element used to transmit power between a set of grooved pulleys or sheaves. The classic v belts are the most common and economical v belt used in the power transmission industry.

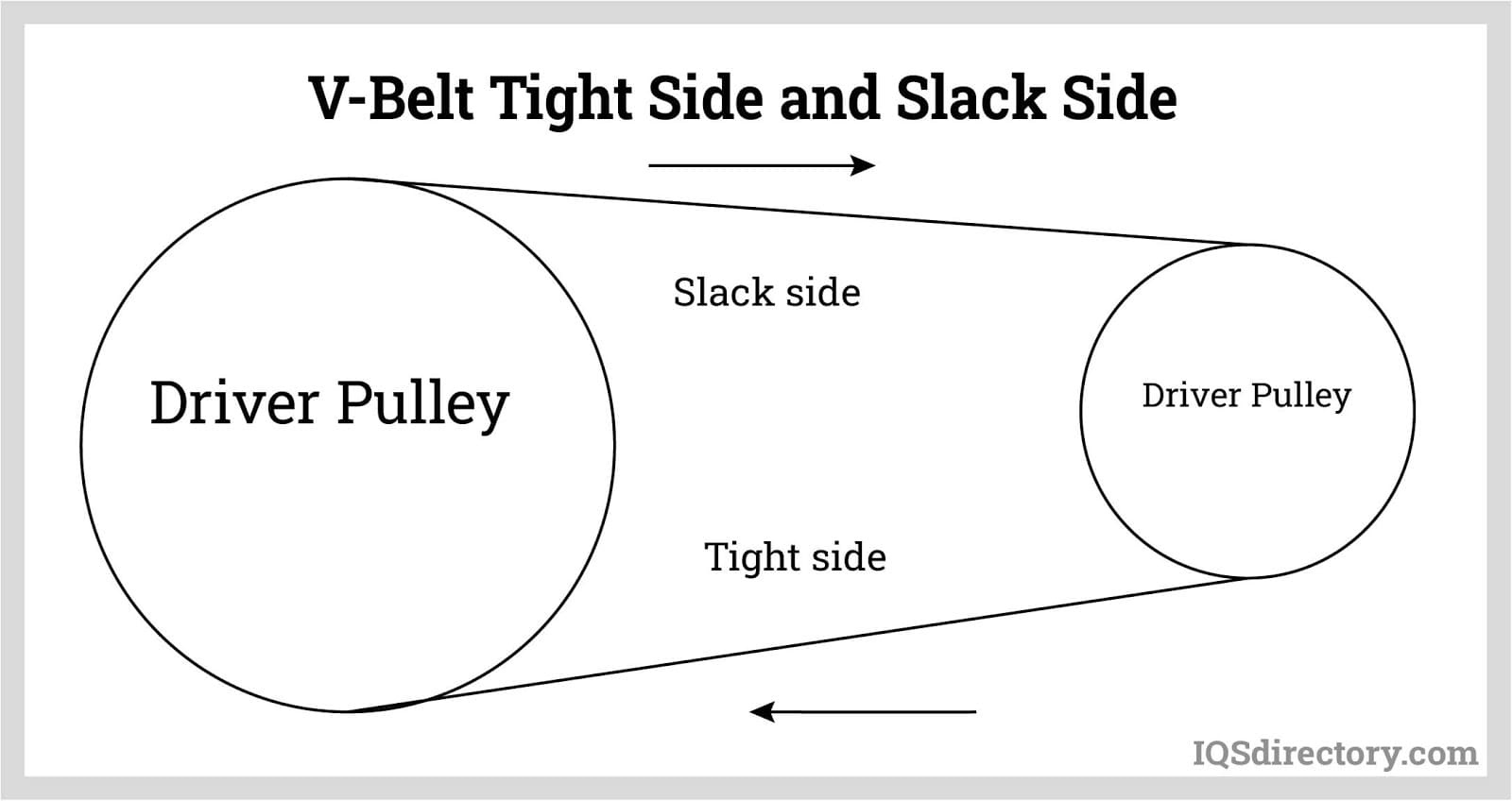

These are used in many industries such as industrial agricultural material handling HVAC and much more. A series of V Belts used to drive a gearbox from the motor. When there is insufficient friction between the belt and pulley the belt revolves through without taking the driven pulley.

Flat belts are also used to transmit power from one shaft to another. 05012005 A belt is a loop of flexible material used to link two or more rotating shafts mechanically most often parallel. These belts are used to transfer power from the crank or cam shaft to the alternator power steering pump and various other accessories.

Ultimate tensile strength UTS. In belt the multiple drives are possible. They provide the best combination of traction speed of movement load of the bearings and long service life.

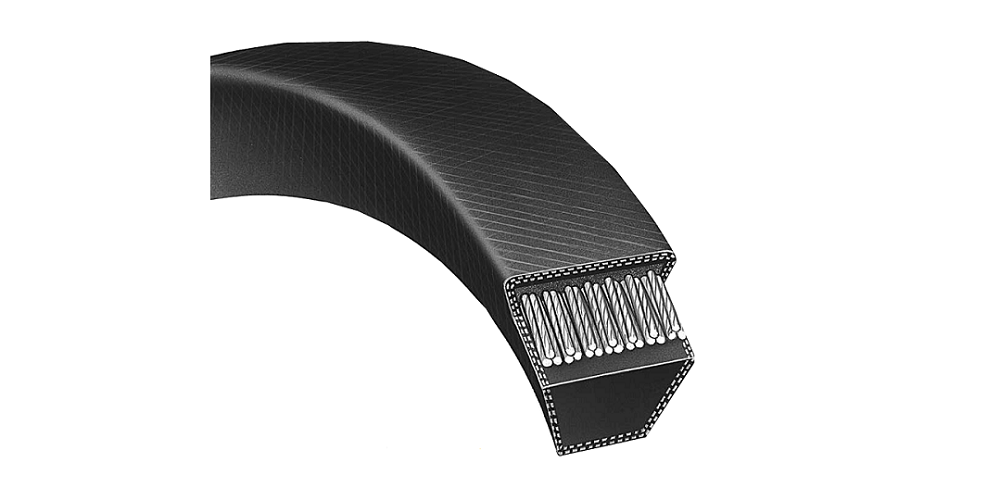

V belts are in the trapezoidal cross-section. Belts may be used as a source of motion to transmit power efficiently or to track relative movement. Specifications for V-belts and V-ribbed belts include.

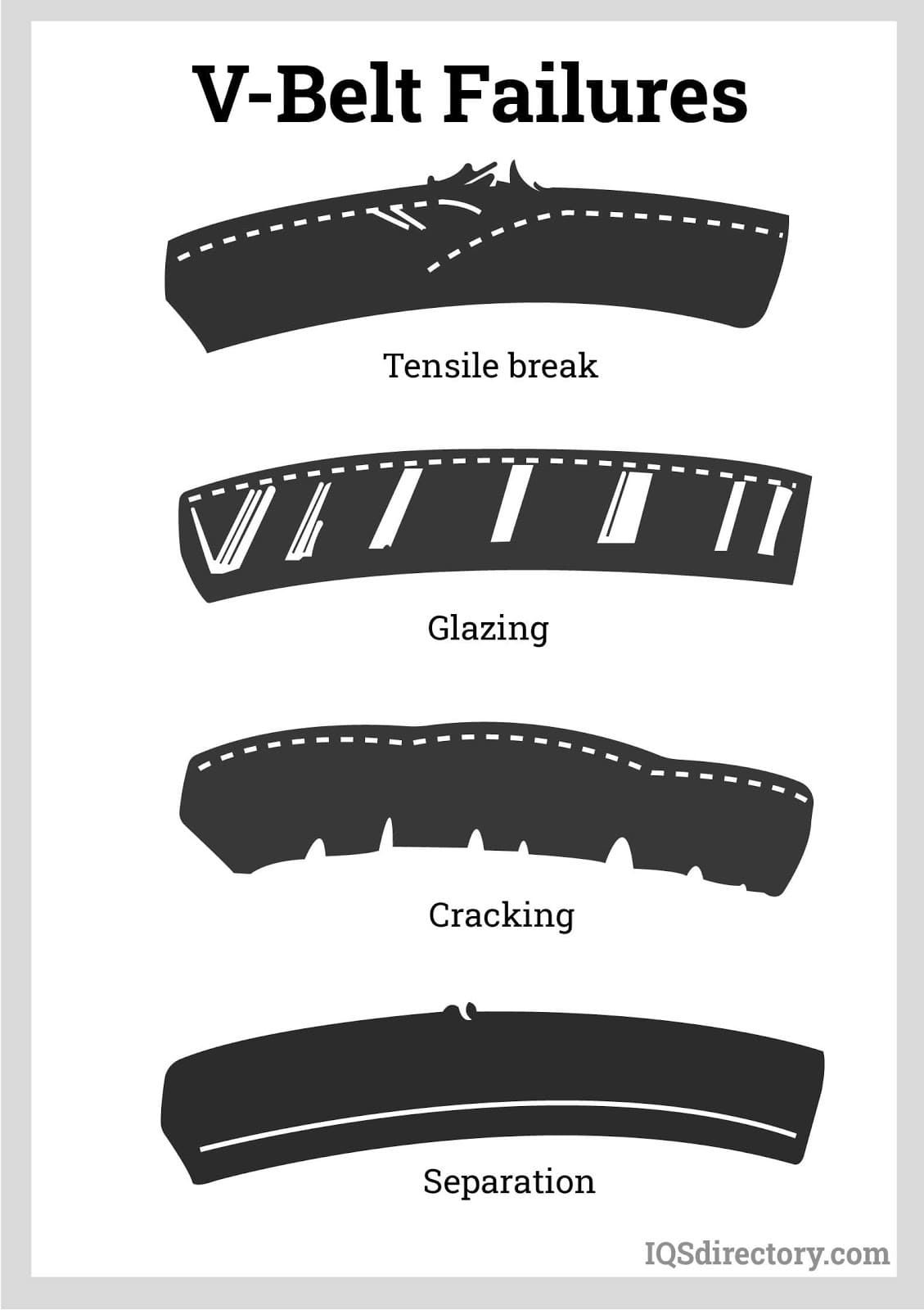

Joined V-Belts For applications with vibrating or pul-sating loads especially with long cen-ter distances joined V-belts may be the answer. In this Video we will explaining Basic characteristics and selection of v-belt There are 3 common belt designs in mechanical maintenance. Misalignment is a common cause of premature belt failure.

V belts are used where shaft distance is less than 2 meters and also used for moderate speed and high power. A V Belt is commonly used in the Lathe. V-belt pulleys are solely used for transmitting power between two parallel axels.

V belt drive has a trapezoidal cross-section and is used with grooved pulleys to transmit high power between short distances. A joined V-belt increases lateral ri-gidity to reduce belt whip and main-. It is a circular cross-section.

These grooves guide and gain traction on a v-belt. In a two pulley system the belt can. Metric V-belts have profiles that adhere to international standards set by organizations such as ISO International Organization for Standardization and DIN the German Institute for Standardization Figure 5.

Its design is for relatively light loads. The most notable difference between a v-belt pulley and other types of pulleys round belt flat etc would be the geometry of the groove or grooves located around the circumference of the pulley. They are characterized as belts having a trapezium cross-section.

02092018 To increase friction or wear resistance and to protect the belt from harmful external influences the V-belt can be covered with a special rubber fabric. There are three basic types of power transmission belting. 22022010 Well here are some typical application areas of V Belt.

Belts are looped over pulleys and may have a twist between the pulleys and the shafts need not be parallel. V-belts are the workhorse within industry available from virtually every distributor and adaptable to practically any drive. 27092013 A drive belt is a flexible loop of rubber or another similar material that is used to connect two or more pulleys.

V-ribbed pulleys are often used with mating belts for efficient very high speed power transmission. They are used to replace belts on industrial machinery manufactured in other parts of the world. This is then referred to as a wrapped V-belt.

Such wrapped V-belts are used for example in drives for pumps in the chemical industry to convey aggressive media. V belts also style V-belts vee belts or less commonly wedge rope solved the slippage and alignment problem. They are presently available in a wide variety of standard sizes and types for transmitting almost any amount of load power.

What is slip in belt drive. Standard v belts are manufactured from a special formulated rubber and reinforced high strength polyester cords for uniformity. The common applications for this V-belt type are domestic washing machines small fans refrigerators and garage equipment.

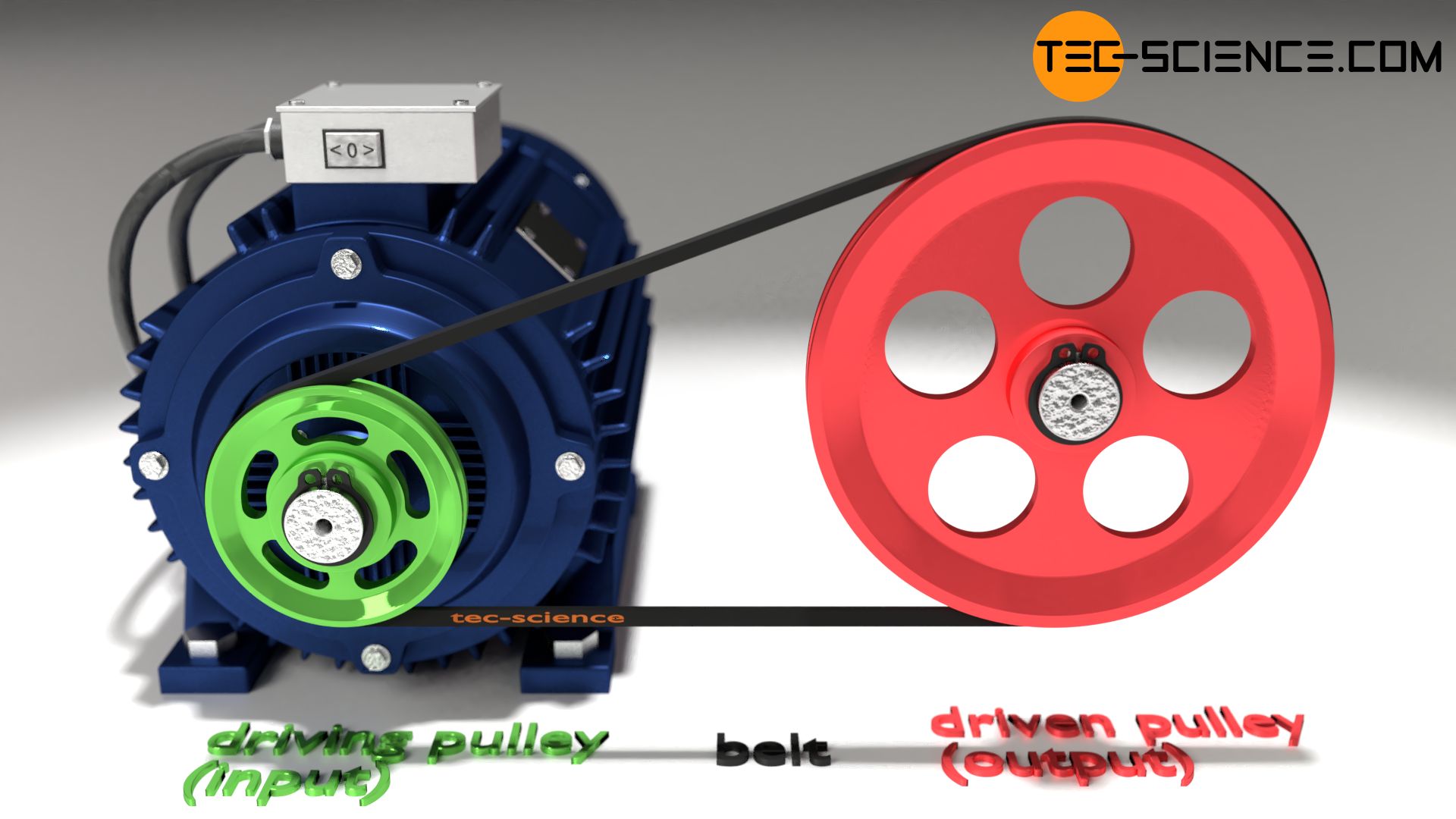

How Does A Belt Drive Work Tec Science

How Does A Belt Drive Work Tec Science

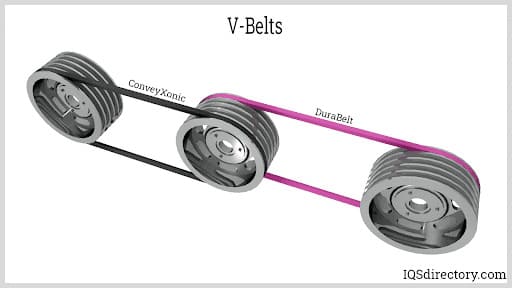

V Belt What Is It How Does It Work Types Of Uses

V Belt What Is It How Does It Work Types Of Uses

V Belts Vee Belts Drives Distributor Minneapolis Mn Rapid City Sd

V Belts Vee Belts Drives Distributor Minneapolis Mn Rapid City Sd

Raw Edge Vs Wrapped V Belts Baart Industrial Group

Raw Edge Vs Wrapped V Belts Baart Industrial Group

V Belt What Is It How Does It Work Types Of Uses

V Belt What Is It How Does It Work Types Of Uses

The Common Types Of V Belts Their Standard Sizes

The Common Types Of V Belts Their Standard Sizes

V Belt Drive Advantages And Disadvantages Mecholic

V Belt Drive Advantages And Disadvantages Mecholic

V Belt What Is It How Does It Work Types Of Uses

V Belt What Is It How Does It Work Types Of Uses

V Belt Code Guide Spec Sense Youtube

V Belt Code Guide Spec Sense Youtube

Choosing The Right Transmission Belt Buying Guides Directindustry

What Is The Difference Between A V Belt And A Serpentine Belt Motor Vehicle Maintenance Repair Stack Exchange

What Is The Difference Between A V Belt And A Serpentine Belt Motor Vehicle Maintenance Repair Stack Exchange

Mechanics Of Machines Belts Ropes Drive Presenters P

Mechanics Of Machines Belts Ropes Drive Presenters P