V-belt pulleys also called vee belt sheaves are devices which transmit power between axles by the use of a v-belt a mechanical linkage with a trapezoidal cross-section. This video demonstrates how to properly align the sheavepulley with the flywheel and set the proper V-belt tension.

Serpentine Belt Noise Everything You Need To Know

Serpentine Belt Noise Everything You Need To Know

When assessing shaft loads please take into account the differing belt pulls in stationary and operational modes.

Using v car fan belt pull loads. Applications up to 8000 rpm. So if we just look at the fan shaft you have your fan on the left-hand side. This is the fan color.

V-belt drives can operate satisfactorily over a wide range of tensions. 27022010 Since a belt-driven fan increases speed and airflow with engine speed it can move more air at higher engine rpm - usually above 2400 rpm - than an electric fan. The ideal tension is the lowest tension at which the belts will not slip excessively at the highest load condition.

3 Wedging action permits a smaller arc of contact increases the pulling capacity of the belt and consequently results in an increase in the power transmission capacity. Conversely electric fans move more air than belt-driven fans at engine speeds below 2400 rpm in typical applications. V-belts are the most common type of belt.

The major advantages of V-belt are as follows. This will result in the best belt life and lowest shaft loads. 26052019 Scroll to the bottom for the YouTube tutorial on this article.

T 1 Tight Side Tension pounds T 2 Slack Side Tension pounds HP Design Horsepower V Belt Speed feet per minute. Ideally when a 10 PSI pressure is placed between the pulleys on the belt the belt deflection should equal the distance between the centerline of the pulleys divided by 64. Together these devices offer a high-speed power transmission solution that is resistant to slipping and misalignment.

However this ideal tension is hard to determine and difficult to maintain. For example in the gear shaft assembly depicted in Fig. This page explains the basic principles of.

Guidelines for elongation at fitting ε with head drives The minimum operational elongation at the fitting for a head drive is Conveyor at rest F W1F W22 FFε SDb 0 N εFU2 2F2. 24072012 Select a Flex Fan for. V-Belt Tension Belt Effective Pull T 1 - T 2 33000 Where.

They are typically used for hauling and lifting loads but can also be used to apply tension within a system such as in a Tensioned Line or Tyrolean. V belts cannot slip out of their pulleys like some of the other belts. As a result timing belts dont slip like other belts do so the pulleys remain in sync.

The preferred center distance is larger than the largest pulley diameter but less than three times the sum of both pulleys. V-belts trump flat belts with their small center distances and high reduction ratios. These grooves guide the belt and allow it to gain traction.

47 the applied bearing loads can be found by using formulas 410 and. 1 V belts are used for short distance which results in compact construction. The number one cause of a power transmission belt failure is improper.

Even though a compressor is used for dem. Or trapezoidal shaped cross section which corresponds to the shape of the pulley they rest in. As shown in the image below an induction motor is connected via a belt to drive two pulleys which will move centrifugal fan.

18042012 Belt tension is normally adjusted by loosening the motor mount bolts and sliding the motor closer or farther away from the fan. 2 Due to wedge action between the belt and the pulley the slip is less. Good cooling with less drag than clutch fans at high rpm.

Pulley systems are used to provide us with a mechanical advantage where the amount of input effort is multiplied to exert greater forces on a load. You cant see it but theres a pulley system and a belt and then theres two bearings supporting this fan shaft. BChain or belt factor Table 44 42 Bearing load distribution For shafting the static tension is considered to be supported by the bearings and any loads acting on the shafts are distributed to the bearings.

19062017 The electric motor is belt driven from the fan shaft so you have a buffer to cut between the pulley and the belt. T 1 Tight Side Tension pounds T 2 Slack Side Tension pounds HP Design Horsepower V Belt Speed feet per minute Total Belt Pull T 1 T 2 33000 25 - G Where. They have a V.

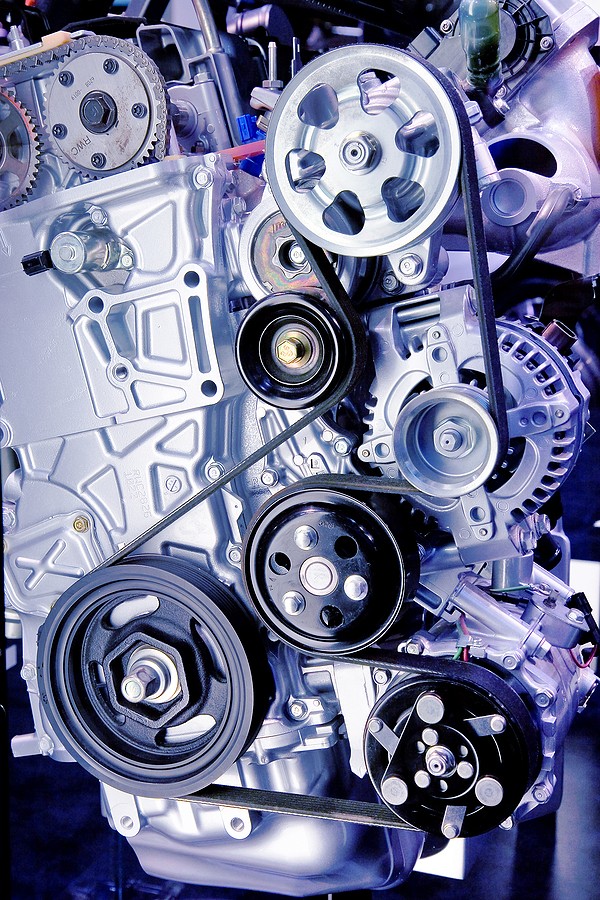

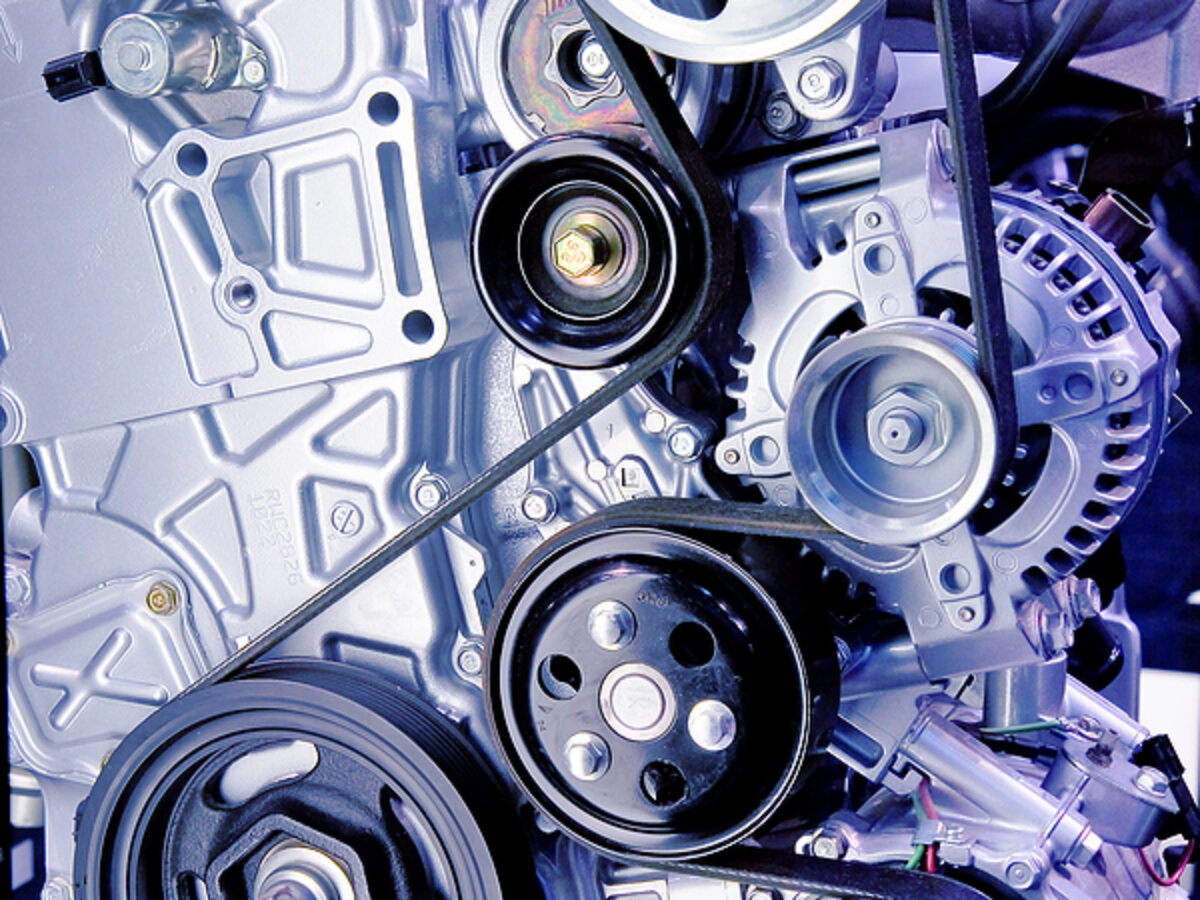

What makes a V-belt pulley stand out from other types of pulleys such as a round belt or flat pulley are the V-shaped grooves of the pulley. Some mechanisms like XY gantries use timing belts and mount parts to the belts to control their position. Range x of 1 of the belt length is therefore sufficient.

05022018 A V-belts purpose is to transmit energy between two components. V-belts need larger pulleys for their thicker cross-section than flat. This is this fairly typical of what you might find to in an Air Handling Unit or AHU.

Mechanical fans also called belt-driven fans are an ideal choice for stock or mildly modified street vehicles but they have some significant performance disadvantages. Optimal speed range is 10007000 ftmin 3002130 mmin.

Introducing Powermaster 37293 Alternators Altr 140a Chrm 1wre Get Your Car Parts Here And Follow Us For More Updates Alternator Car Alternator Pulley

Introducing Powermaster 37293 Alternators Altr 140a Chrm 1wre Get Your Car Parts Here And Follow Us For More Updates Alternator Car Alternator Pulley

What S The Difference Between A Drive Belt And A Timing Belt Quora

What S The Difference Between A Drive Belt And A Timing Belt Quora

Engine Knock Rattle Accessory Belt Pulleys Or Engine Internals Youtube

Engine Knock Rattle Accessory Belt Pulleys Or Engine Internals Youtube

How To Tell If A Timing Belt Tensioner Is Bad 6 Steps

How To Tell If A Timing Belt Tensioner Is Bad 6 Steps

How To Check Adjust Serpentine Drive Belt Tension On Your Car Youtube

How To Check Adjust Serpentine Drive Belt Tension On Your Car Youtube

What Is Serpentine Belt When Should You Replace It Engineering Choice

What Is Serpentine Belt When Should You Replace It Engineering Choice

2007 Jeep Compass Serpentine Belt Routing Diagram 5 2007 Jeep Compass Jeep Compass Jeep

2007 Jeep Compass Serpentine Belt Routing Diagram 5 2007 Jeep Compass Jeep Compass Jeep

What Is Serpentine Belt When Should You Replace It Engineering Choice

What Is Serpentine Belt When Should You Replace It Engineering Choice

Tech Tips Understanding Belt Friction And Tension

Tech Tips Understanding Belt Friction And Tension

Why Does My Engine Belt Squeal Bluedevil Products

Why Does My Engine Belt Squeal Bluedevil Products

Stretch Belts In Depth Know Your Parts

Stretch Belts In Depth Know Your Parts

Serpentine Belt Noise Everything You Need To Know

Serpentine Belt Noise Everything You Need To Know