312 Calculating Belt Static Tensions T st Using an average coefficient of friction and the wedging effect of the average groove angle 38 degrees it can be shown that at 180 degrees of wrap a practical level of V-Belt operating tension can be achieved with a 51 ratio between the tight side tension and the slack side tension. V-belt is the rubber belt that drives things such as the alternator air conditioning compressor power steering pump and waterpump.

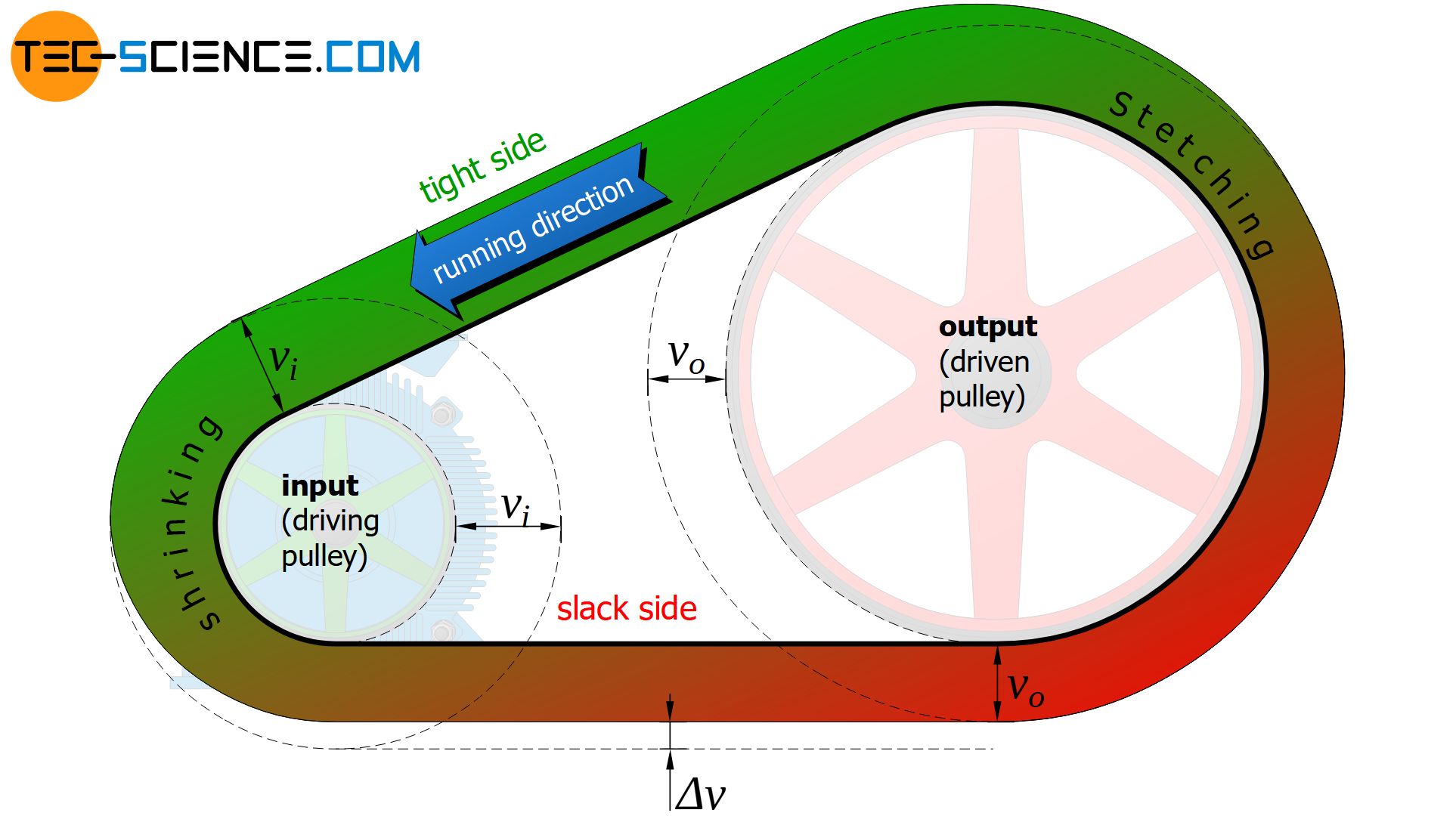

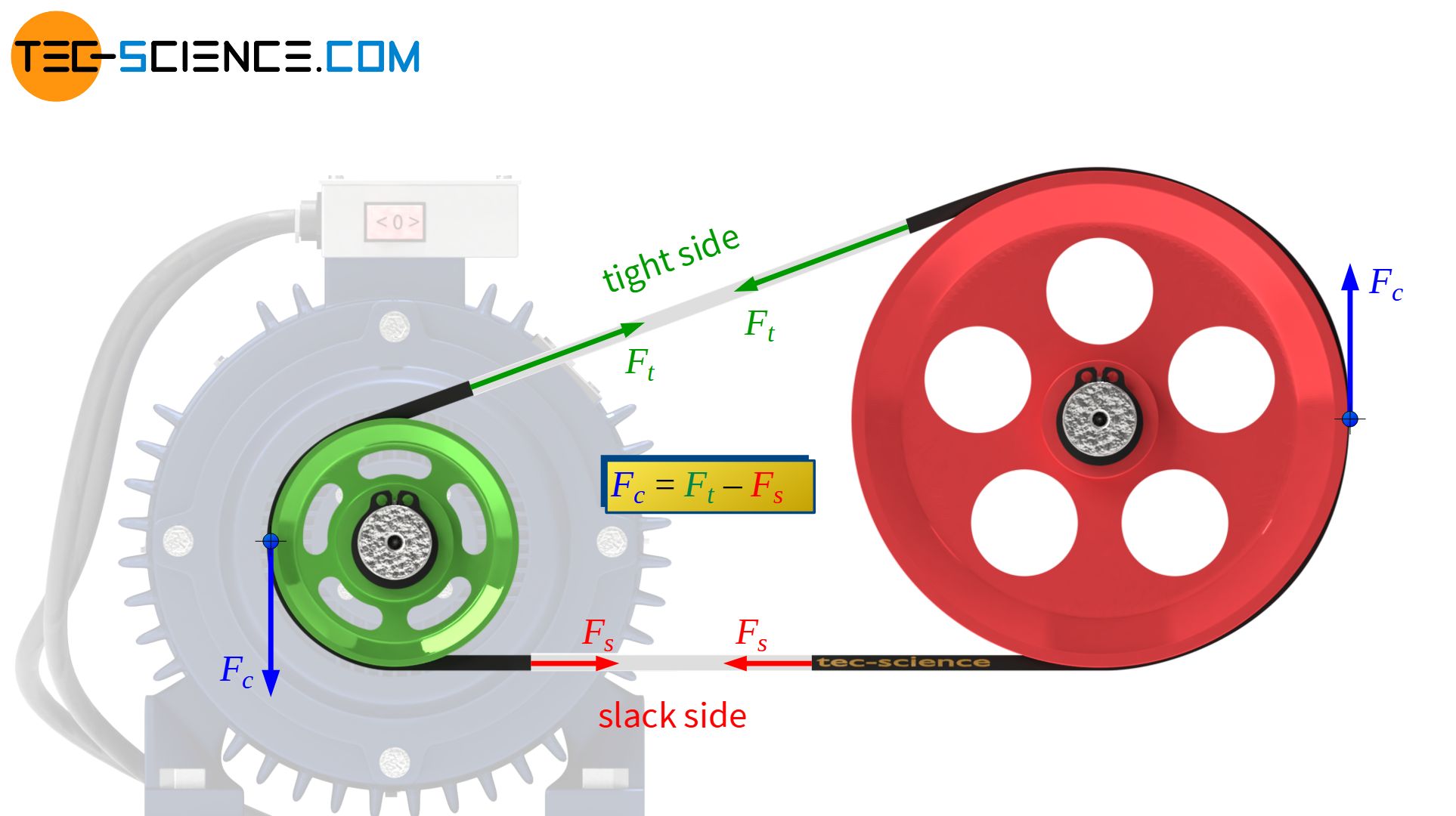

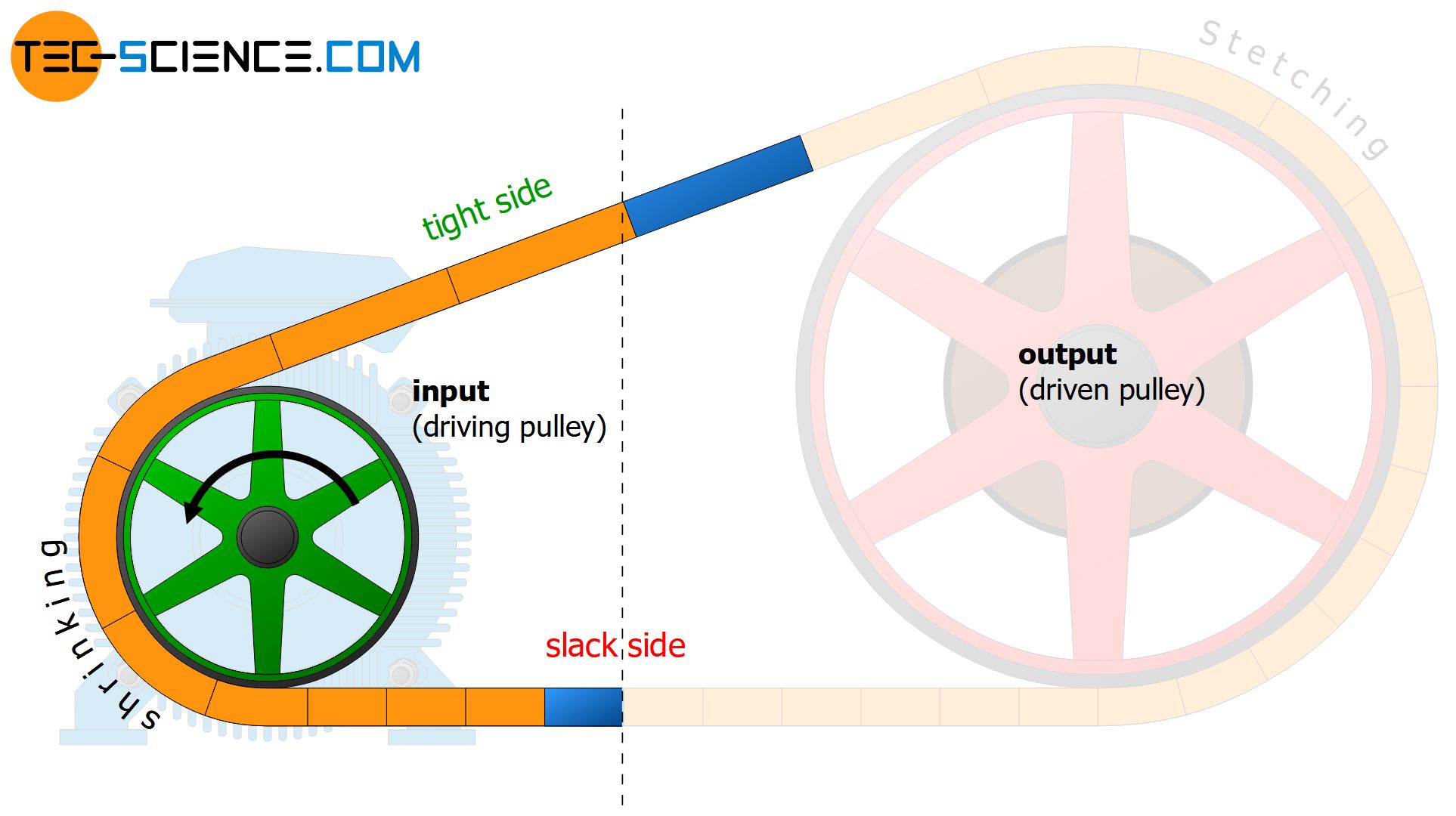

Slippage Of The Belt In Belt Drives Tec Science

Slippage Of The Belt In Belt Drives Tec Science

Make V-Drive inspection on a periodic basis.

Calculating v belt slipping point. θ a 180. W was provided in the question as 250 rev min but I needed the answer to be converted to seconds. Speed ratio N a N b r b r a 100 s 100.

TA 90 T Ae 03 111 sin 0106 245T A. This is at the AP Physics level. Guidelines for elongation at fitting ε with head drives The minimum operational elongation at the fitting for a head drive is Conveyor at rest F W1F W22 FFε SDb 0 N εFU2 2F2.

X Research source However its a good idea to check your belts on a regular basis. S percentage slip. The application of a V-belt changes only the friction equation.

It is used where low power is required and speed is more. The belt also tends to wedge into the groove as the load increasesthe greater the load the greater the wedging actionimproving torque transmission and making the V-belt an effective solution needing less width and tension than flat belts. Lift the plunger from the belt and read the pounds of.

How you can use this though is a tool to visualize how far into a groove your belt might ride into the v-belt pulley youre considering. V-belts also known as Vee belt or wedge rope are an early solution that solved the slippage and alignment problem. Place the plunger end of the tension gauge on the top of the belt.

Measure the distance between the two pencil marks to determine the circumference of the V belt. The reduced tensions help increase bearing life. When pulley b is the driver Arc of contact rarb.

Ideal tension is the lowest tension at which the belt will not slip under peak load conditions. Therefore the linear speed of the belt would be 2618 0075 19635 meters per second Assuming no slip. V velocity of belt ftmin n m revolutions motor rpm - or alternatively in metric units.

Modifying the friction equation changes the solution to. 05022018 Designed for the tension testing of a drive with two or more belts this pocket-sized tool measures V-belts from 10 to 170 and up to 35 pounds of tension. Ring on the plunger is even with the top of the wood.

This is a kind of rectangular cross-section. Tension ratio for belt about to slip. The velocity at which a belt travels may be expressed as.

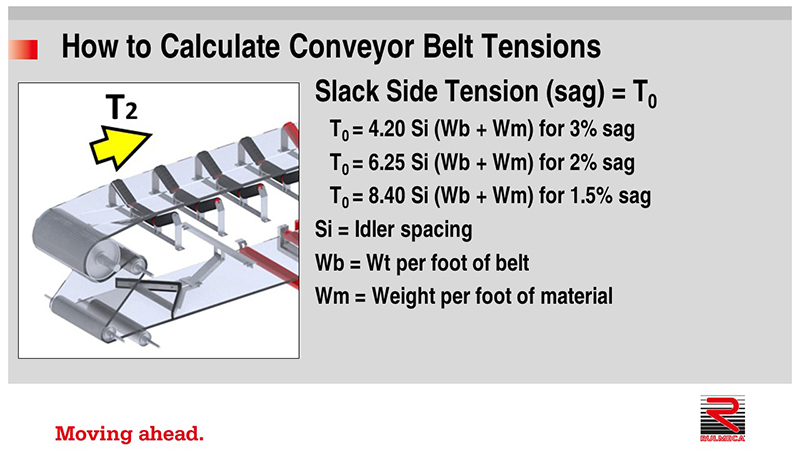

In order to find the maximum tension is necessary to calculate the effective tension that is the force required to move the conveyor and the load at a constant speed. In a V belt the enhanced. Shape of the belt tracks in a mating groove in the pulley or sheave with the result that the belt cannot slip off.

V b velocity of belt ms d mb diameter motor pulley m. Its called a V-belt because of its V shaped cross-section. Keep belts free from foreign material which may cause slip.

Coefficient of friction takes into account the coefficient of friction between the two materials as well as the groove angle. As we can see from the equation above steeper sides to the groove which would result in a smaller angle alpha result in an increased potential difference in the tension forces. θ b 180.

TA 382lbf and TB 984lbf Notice the efficiency increase of a V-belt over that of a flat belt. V b π d m n m 60 2b where. Generally the shaft distance is between 5 to 10 meters.

2 sin 1 r a r b L. Measure belt span and measure the force required to deflect any one of the belts 164 for every inch of span length. Explains how to calculate the magnitude and direction of a magnetic field that is created by a moving point charge.

V π d m n m 12 2 where. Flat belt V belt and Circular belt Timing belt. So 250 2pi60 2618 radians per second.

If you place two pins on either side of the grooves on a v-belt pulley and measure the distance you will get the Overpin diameter. 2 sin 1 r a r b L. Place a second pencil mark on the flat surface to designate the contact point of the paint mark with the flat surface.

Roll the V belt along the flat surface until the paint mark rolls back to the flat surface. Ideally once a month. 17012017 The equation I would use to work out Linear speed is given as v wr.

06052021 According to the Car Care Council V-belts should be replaced every four years or 36000 miles 58000 km while serpentine belts are designed to last for up to 50000 miles 80000 km. The 38o V is 0211 radians. 60 x v v Q 0278Qt or Q Qt Kgm v 3600 x v 2.

Lets study these four belts in detail. V belt velocity. Over tensioning shortens belt and bearing life.

Check tension frequently during the first 24-48 hours of run-in operation. Holding the tension gauge vertical to the belt press down until the bottom of the O. Range x of 1 of the belt length is therefore sufficient.

When assessing shaft loads please take into account the differing belt pulls in stationary and operational modes.

Slippage Of The Belt In Belt Drives Tec Science

Slippage Of The Belt In Belt Drives Tec Science

Finding The Length Of A Belt Using Radians And Simple Geometry Youtube

Finding The Length Of A Belt Using Radians And Simple Geometry Youtube

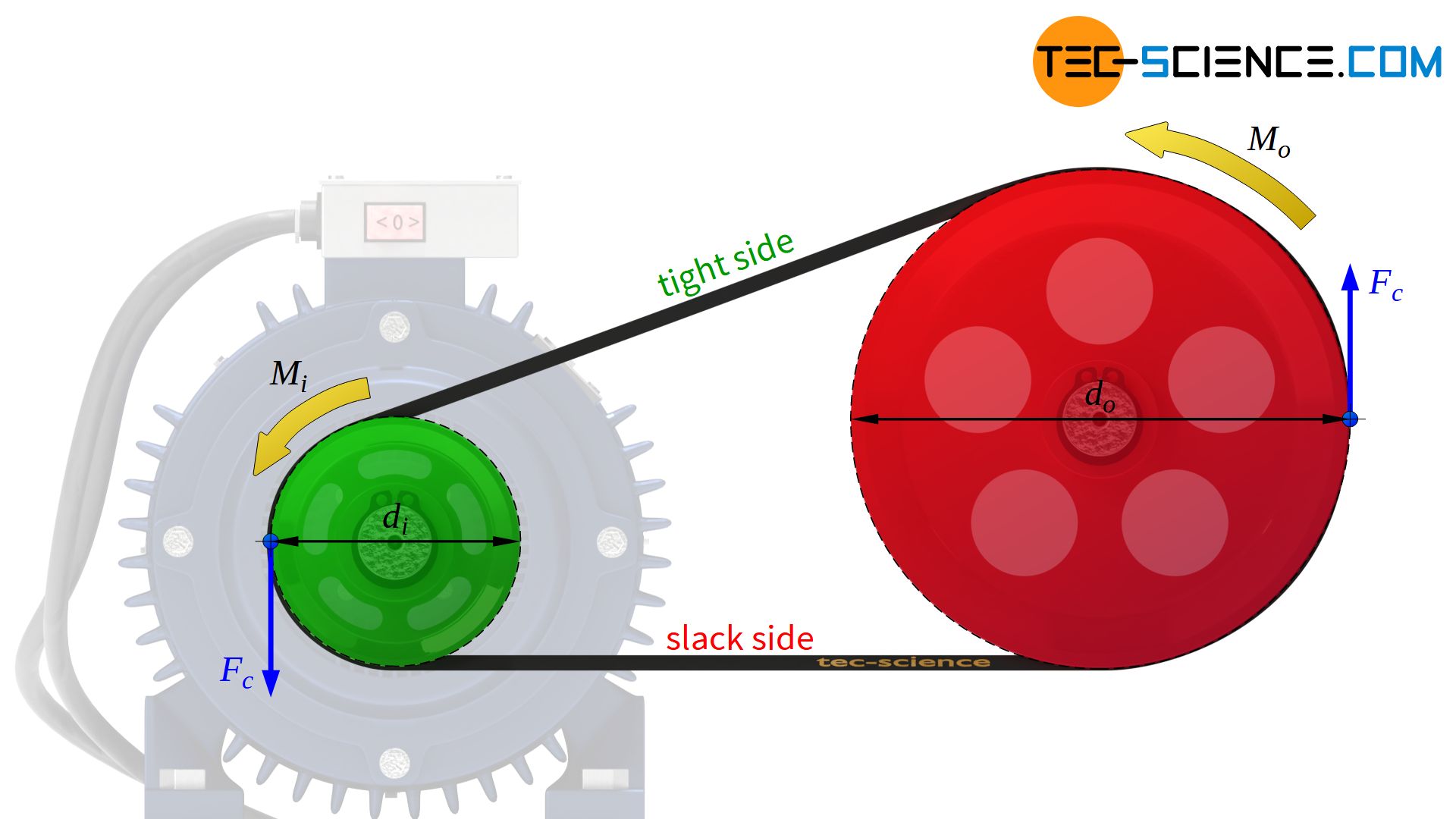

Power Transmission Of A Belt Drive Tec Science

Power Transmission Of A Belt Drive Tec Science

Slippage Of The Belt In Belt Drives Tec Science

Slippage Of The Belt In Belt Drives Tec Science

Slippage Of The Belt In Belt Drives Tec Science

Slippage Of The Belt In Belt Drives Tec Science

Pdf Microslip Friction In Flat Belt Drives

Pdf Microslip Friction In Flat Belt Drives

Slippage Of The Belt In Belt Drives Tec Science

Slippage Of The Belt In Belt Drives Tec Science

Pdf Mechanics Of Serpentine Belt Drives With Tensioner Assemblies And Belt Bending Stiffness

Pdf Mechanics Of Serpentine Belt Drives With Tensioner Assemblies And Belt Bending Stiffness

How To Video Index Conveyor Drive Design Maintenance Tips Rulmeca Corp

How To Video Index Conveyor Drive Design Maintenance Tips Rulmeca Corp